Environmental Engineering Reference

In-Depth Information

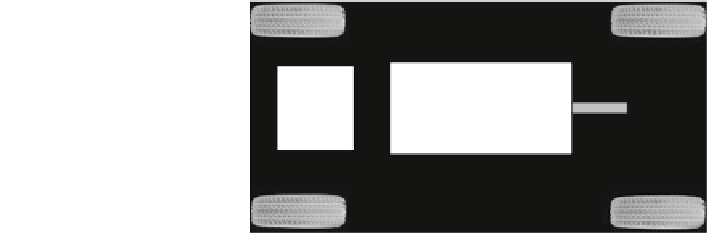

Fig. 5.1 Electric and

mechanical connections

between the main compo-

nents of a BEV

T

RASMISSIO

N

BATTERY

PACK

Electric Drive

Nowadays the worldwide market offers a range of electric vehicles which

fundamentally use the configuration described in Fig.

5.1

. For example, from the

smallest to the biggest ones it is possible to mention: electric bicycles, electric

wheel chairs, tricycles, small commuter vehicles, delivery vehicles, electric golf

buggies, electric cars, delivery trucks and buses. The fact of the matter is that

private electric cars do not play an important role in the field of BEVs, but each of

the above types of vehicles fills a different niche in its specific market.

The scheme of Fig.

5.1

represents the base of all other types of electric vehi-

cles, both those using an additional traction engine on board (HTEV) and those

adopting alternative storage/generation electric energy systems to power the

electric drive (hydrogen fuel cell electric vehicles, HFCEV, solar vehicles and

vehicles using flywheels and supercapacitors).

5.2 Electric Drives for Road Vehicles

The main characteristics of electrical drives are reported in this section from the

point of view of the application of these components to road electric vehicles.

Electrical drives are composed of rotating electric machines (which transform

electric energy into mechanical energy or viceversa), power electronic converters

and controllers connected together in order to operate the whole electrical drive in

steady state or variable speed working operations.

Rotating electric machines fundamentally can be subdivided in two main types:

direct current (DC) machines and alternating-current (AC) machines. All types of

rotating electric machines have a stationary part, called stator, and a rotating part,

called rotor. Generally the rotor is connected to a shaft which the mechanical

torque acts on.

In rotating electrical machines, several conductors are distributed along the

inner and outer sides of the air gap between rotor and stator, which are electrically

excited. These conductors carry currents in the rotor and stator conductors creating

resultant magnetic fields, which vary in space and time. The interaction between

the two magnetic fields causes a resultant electromagnetic torque, which have a

very important effect on the steady-state and transient behavior of the machine.