Environmental Engineering Reference

In-Depth Information

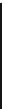

Load

Hydrogen

purge

DC/DC

Membrane

humidifier

Pressure

regulator

Hydrogen tank

Air

exhaust

Heat exchanger

humidifier

H

2

O

Back pressure

regulator

Fuel Cell

Air

compressor

M

Heat

exchanger

Reservoir

Fan

Water

pump

Start-up

battery

M

Fig. 4.9

Example of a low pressure H

2

FCS integrated plant

content of the exhaust cathodic stream, and in minor quantities of the anode outlet

stream. The recovered water could be used as feed of humidifiers installed in the

entrances of the stack for oxidant or for both reducing and oxidant streams,

concurring to the operation of stack in water neutral conditions, improving reli-

ability of the power generator.

4.6.1 FCS Efficiency

The behavior of fuel cells in terms of individual and overall voltage as function of

current density represents the basic performance from which an overall efficiency

evaluation has to start. The impact of the parasitic consumption of auxiliary

components involved in the system management strategies on the net power

produced by the fuel cell stack represents the second important step to be carefully

evaluated.

The main ancillary components that concur to reduce the gross stack power are

reported in Fig.

4.10

. The auxiliaries are actuated electrically, and the total DC

power produced by stack is partially consumed by the motors that move the

compressors and pumps, and by the electricity necessary to supply the radiator fan

and the controller.

The power consumption of ancillary components results particularly significant

in the low power ranges [

44

], and among them the air compressor provides the