Environmental Engineering Reference

In-Depth Information

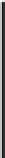

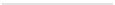

In Fig.

4.6

a scheme of cooling circuit related to FCS for automotive appli-

cation is shown. The main components are the pump for liquid circulation, the

water reservoir and the heat exchanger with fan. For small size stacks (from 100 to

500 W) it is possible to use only air forced by fan to cool directly the stack, while

for higher powers, more suitable for automotive requirements (1-100 kW), it is

reasonable to use an internal coolant circuit fed by a liquid, such as de-ionised

water or ethylene glycol-water mixtures, to improve the heat removing capacity of

an order of magnitude with respect to the gas.

The stack cooling is not the unique aspect to be examined in the context of FCS

thermal management, but also the possibility of heat recovery has to be also

considered. At this regard, additional devices have to be used, such as air-to-air

heat exchangers, humidifiers, or condensers that partially exploit the enthalpy

content of cathode outlet and coolant streams [

23

]. In particular enthalpy wheels,

which are rotary air-to-air heat exchanger, can be used to preheat the inlet

exploiting the enthalpy content of the wet and warm cathode outlet stream, which

is a gaseous mixture at the approximately the same temperature of the stack in

saturated conditions. They transfer mainly heat but allow also moisture to be

exchanged. The device is quite compact and can achieve high energy transfer

effectiveness. It is constituted by a cylinder filled with a permeable material with

high surface area (polymer, aluminum, or synthetic fiber), necessary for the sen-

sible heat transfer. The driving force for realizing the exchange is the thermal

gradient between the opposing air streams.

The enthalpy exchange is accomplished through the use of typical adsorbent

materials such as silica gel, zeolites or other molecular sieves which transfer water

molecules by the difference in the partial pressure of vapor within the opposing air

streams. The operation of a FCS that includes this component requires specific

Temperature

sensor

Temperature

sensor

Fuel Cell

Pump

Water

Reservoir

Heat

exchanger

Fan

Fig. 4.6

Water cooling sub-system for H

2

FCS