Environmental Engineering Reference

In-Depth Information

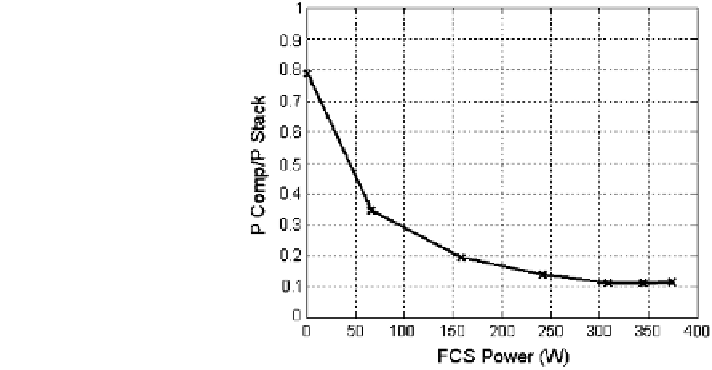

Fig. 3.9 Effect of air com-

pressor consumption for a

500 W PEM stack

compressor consumption (about 10% of stack power) is obtained for high output

power (from 200 W up to maximum load) maintaining the stoichiometric ratio not

higher than 2, while at low loads the necessity to maintain a minimum air flow rate

implies that the energy losses due to the compressor represent a large fraction of

the power supplied by the stack.

3.4 Durability of PEM Fuel Cells

Durability is a fundamental and necessary feature for PEM fuel cells to see a wide

diffusion as a practical power source in any application field. The requirements for

fuel cell lifetime vary with the specific application, in particular a duration of at

least 5000 h is mandatory for use on cars, while even longer periods are needed for

bus and stationary employments (for most applications an acceptable degradation

rate is considered to be comprised in the range 2-10 lV/h [

51

]). However, the wide

variability of operative conditions usually encountered in automotive applications,

such as dynamic driving cycles, startup/shutdown phases, and freeze/thaw, makes

also the target for car very difficult to be met with the current technologies.

Since the concept of durability decay is strictly connected to that of aging, in

the sense of a progressive and not reversible loss of performance, a general

examination of this feature for PEM fuel cells has to include some considerations

about the main processes that can cause the degradation of materials used for

components of these systems (electrocatalysts, membranes, GDL, and bipolar

plates), which is mainly related to working conditions of high humidity and

temperature, oxidizing or reducing environment, and dynamic operation.

As discussed before the amount of platinum catalyst used in electrocatalysts of

a PEM fuel cell is supported on carbon in the form of nanoparticles, in order to