Environmental Engineering Reference

In-Depth Information

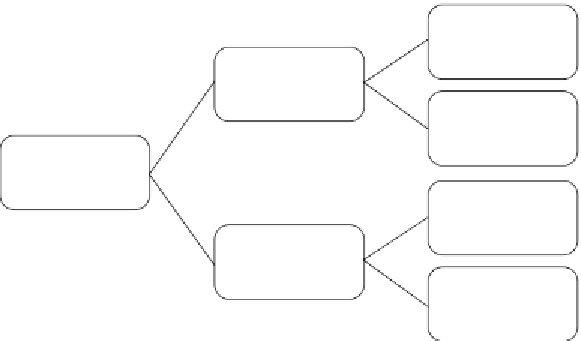

Biocidal

Direct activity

Biofouling

adhesive

degrading

Enzymic anti-

fouling

Substrate from

seawater

Indirect activity

Coating of

surface with

substrate

Figure 2.18

Enzyme technology for anti-fouling

Other anti-fouling enzymes that have received attention are oxidoreductases,

including glucose oxidase and hexose oxidase, which produce hydrogen peroxide

(H

2

O

2

) that may induce oxidative damage in living cells. Kristensen and co-workers

[81] evaluated the anti-fouling potential of H

2

O

2

produced enzymically in a coating

containing starch, glucoamylase and hexose oxidase. After immersing it in sea for

97 days, the control surface with no enzymes had 35−40 barnacles, 10% of the area

was covered by diatoms and 15% of the area was covered by tunicates. The enzyme

coated surface had only 6−12 barnacles, 10% of the area was covered by diatoms

and no tunicates were present. The enzyme coated surface performed in a similar

way to a copper-based commercial coating.

It is known that QS plays an important role in the bioilm formation. AHL are required

for QS by some gram negative bacteria. AHL acylase can be used to degrade AHL.

Cao and co-workers showed that with increase in concentration of this enzyme, the

bioilm formation is inhibited [62].

2.5.3.2 Non-toxic Anti-fouling Coatings: Non-sticking Foul Release

Coating

The foul release coating (FRC) method involves an environment friendly approach.

The design of anti-fouling surfaces are based on minimising the forces of interactions

between the biomolecules and the synthetic surface so that adhered cells are easily

released or dislodged under low shear stresses [10]. A number of polymer surface