Agriculture Reference

In-Depth Information

60

AD film

LDPE film

10 cm

20 cm

30 cm

40 cm

55

50

45

40

35

30

07:00 19:00

07:00

19:00

07:00 19:00

07:00

19:00

Hour

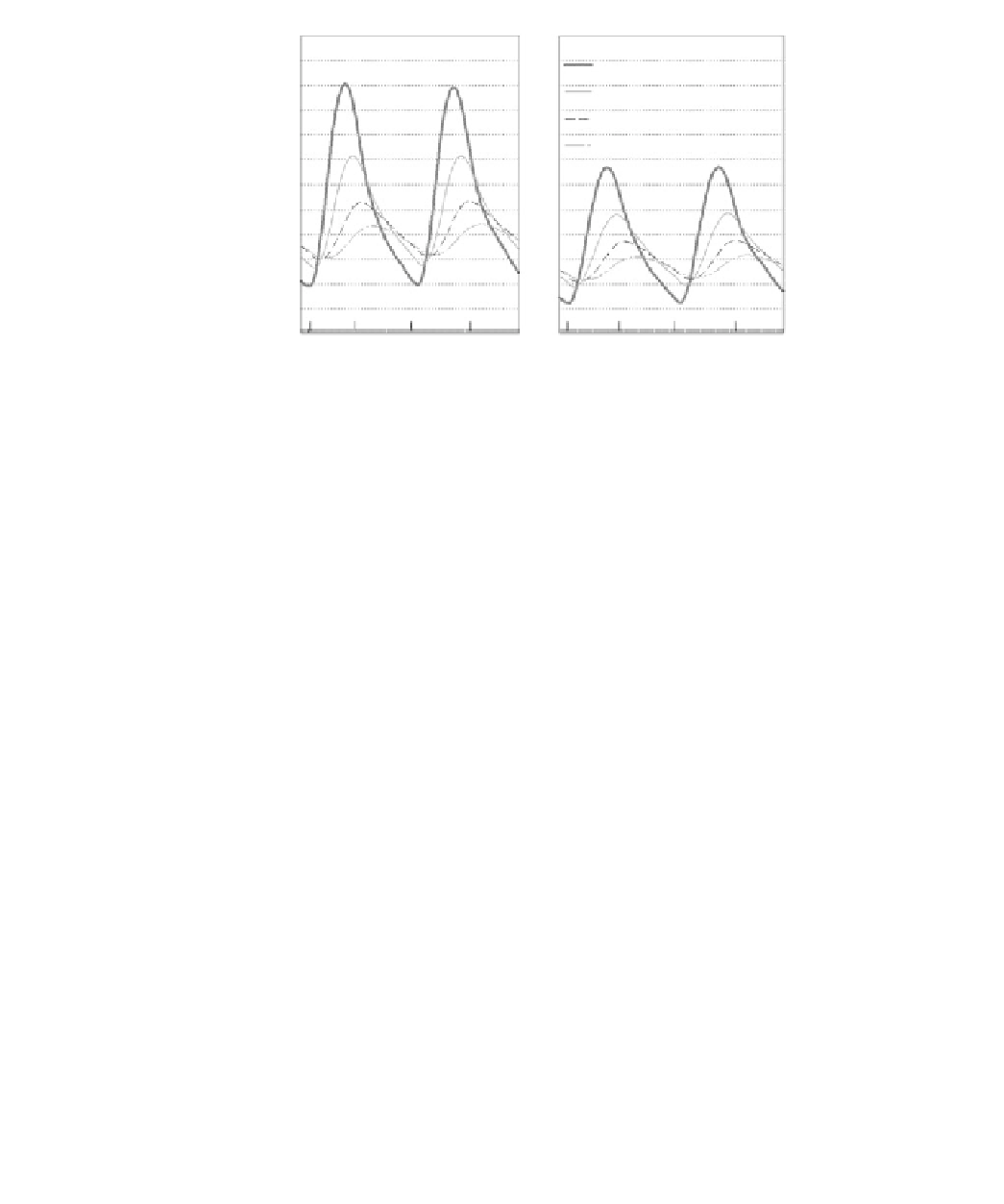

Figure 10.4

Soil temperatures at various depth during soil solarization at the summer time in Israel

using two mulches. LDPE: low-density polyethylene sheets; AD: low-density polyethylene sheets with

addition of antidrip material to the polymer.

10.8

The most common plastic fi lm used for solarization is polyethylene. The thickness of the

fi lm has no considerable effect on soil heating. The sheet is applied at thicknesses as low

as 20

Implementation and application

m with appropriate plastic material. Therefore, the farmer can consider using the

thinnest plastic (which is also the cheapest) available that is still strong enough for his

application technology. Used polyethylene sheets are also effective for SH (Avissar

et al

.,

1986), at practically no cost.

Continuous mulch is desirable for effective SH. It reduces the 'border effect' (Grinstein

et al.,

1995) and also improves control effi cacy and reduces soil reinfestation compared

to strip solarization. However, strip solarization applied to 20-cm high, 0.9-m wide beds,

increased soil temperatures and eliminated the border effect (Chellemi

et al.,

1997). This

is another example of improved technology of solarization. The optimal area for covering

a solarized plot is, of course, the whole fi eld. Such application causes yield improvement

and provides a long-term effect, thus spreading the cost of disinfestation over several

crops. The economic advantages resulting from complete coverage of the plot should be

assessed against the expenses involved.

Relatively small plots can be covered manually. The edges of the sheet should be fi rmly

embedded in the soil, while ensuring fi lm tightness. A continuous plastic covering for

relatively small plots can be achieved manually by anchoring the edge of two adjacent

sheets together in one furrow (Grinstein & Hetzroni, 1991). Mechanized plastic mulch is

essential for use in large plots. This is applied essentially as soil fumigation is performed.

The tarp layer machine unrolls plastic strips (2-4 m width), each of which is anchored to

the soil at one side and connected the other sheet by means of glue or welding. Sheet glu-

ing is most common in soil-fumigation rigs. The glue is sprayed in a 5- to 8-cm strip along

the edge of the previously laid sheet near the border of the anchored area. During the glue

spraying, a new fi lm is unrolled and one side is pressed over the top of the sprayed glue,

μ