Environmental Engineering Reference

In-Depth Information

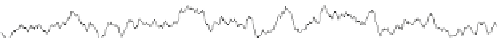

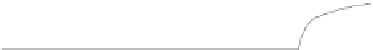

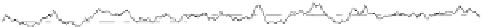

Steady-state

2

1

0

0

100

200

300

400

500

600

700

800

900

1000

Stationary

1.5

1

0.5

0

100

200

300

400

500

600

700

800

900

1000

Transient

1.2

1.1

1

400

420

440

460

480

500

520

540

560

580

600

Quasi-stationary

2

1

0

0

100

200

300

400

500

600

700

800

900

1000

Ti m e

Figure 2.3

Typical variations of process variables for various operating conditions

described by the usual statistical features: the mean μ

x

, the variance

V

x

(

0

)

and the

autocovariance

V

x

(

k

)

(or autocorrelation ρ

(

k

)

if normalized by the variance):

E

(

x

)=

μ

x

;

(2.5)

T

E

((

x

(

t

)−

μ

x

)(

x

(

t

−

k

)−

μ

x

)

)=

V

x

(

k

).

The nature of the reconciliation procedure to be applied to filter industrial data

must be adapted to the operating regime that was prevailing during data gathering,

and to the measurement strategy then applied. There is no systematic method to

decide whether a steady-state, stationary or dynamic filter must be applied, but some

hints can be helpful. Some of the conditions for the application of a steady-state

observer are:

•

The process deviation from a theoretical steady-state is of low magnitude com-

pared with measurement error amplitudes (variance matrix

V

). In other words,

the diagonal terms of

V

are large in comparison with the diagonal terms of

V

x

(

0

)

.

•

The process deviation from a theoretical steady-state is significant with respect

to the measurement errors, but the dynamic variations are produced by stationary

disturbances of high frequency spectra in comparison with the natural process

dynamics - in other words, the process variable autocorrelogram time widths

are small in comparison with the width of the cross-correlation between process

inputs and outputs. However, instantaneous measurements data set could be pro-

cessed by the steady-state method providing that the high frequency disturbance

variances are added to the measurement error variances.

Search WWH ::

Custom Search