Environmental Engineering Reference

In-Depth Information

70

65

60

55

50

150

200

250

300

350

400

450

500

100

80

60

40

150

200

250

300

350

400

450

500

Samples (k)

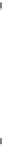

Figure 5.20

Stabilizing controller: percentage of solids and water flow rate

The supervisory level (second level) calculates a set-point for filling level so that

the SAG mill always operates at a point near its maximum possible power draw.

Power draw level is modeled as a quadratic function of mill filling level [37]. The

strategy tries to maximize power draw while keeping all variables within defined

constraints. If no constraint is active, then optimal operation will be obtained when

the gradient of this quadratic function is zero.

40

30

20

150

200

250

300

350

400

450

500

1400

1200

1000

150

200

250

300

350

400

450

500

10

9

150

200

250

300

350

400

450

500

0.2

0

−0.2

150

200

250

300

350

400

450

500

Samples (k)

Figure 5.21

Optimizing controller: filling level, fresh flowrate, mill speed, gradient

Figure 5.21 shows how the supervisory level changes the set-point every 50 min-

utes so that ore feedrate is maximized. Gradient values near zero provide an indica-

tion of being at an optimal value. At time 250 minutes, ore hardness increases and

Search WWH ::

Custom Search