Environmental Engineering Reference

In-Depth Information

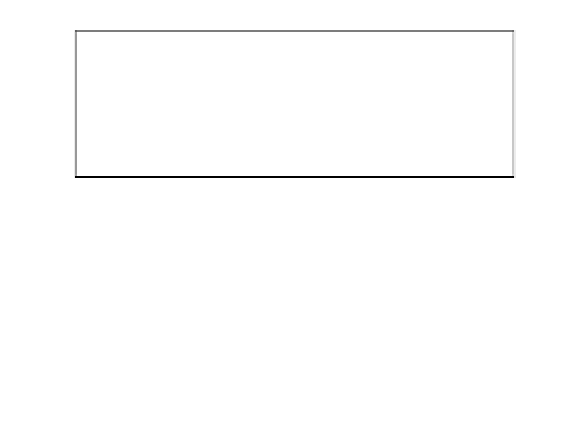

32

30

28

26

1000

1500

2000

2500

3000

3500

4000

1.074

x 10

4

1.072

1.07

1.068

1.066

1.064

1000

1500

2000

2500

3000

3500

4000

Samples (k)

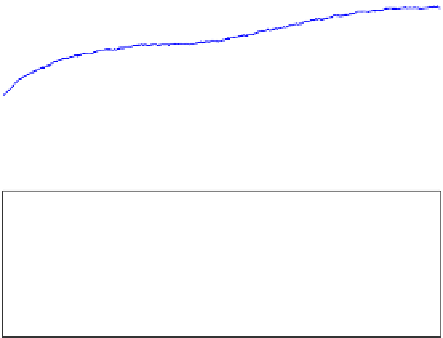

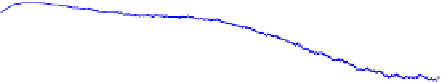

Figure 5.17

Level and power draw for a change in the ore hardness with a 1200 ton/h ore feedrate

Outputs are:

1. power draw (

y

1

);

2. pebbles flowrate (

y

2

);

3. sump level (

y

3

);

4. pulp density of sump output flowrate (

y

4

);

5. level filling (

y

5

);

and disturbances:

1. hardness (

d

1

);

2. feed particle size distribution (

d

2

).

In this application, all output variables are not required to reach a set-point. Some

of them, for example the flow rate of pebbles, are only required to stay within a

certain range.

In the first level, four control loops are implemented: inlet pressure in the hy-

drocyclones is controlled by the number of hydrocyclones in operation. (Therefore,

this variable is considered as constant in this simulation.) Sump level is controlled

by pump speed, considering a model in terms of pump speed, water flowrate and

fresh ore feedrate. Density is controlled by the water feedrate and also considers ore

feed rate as a measurable disturbance. Filling level is controlled by the ore feedrate

and mill speed is subject to constraints in the pebble flowrate. The controller consid-

ers a model including mill speed, fresh ore feedrate and the pebble flowrate, which

is modeled in terms of mill speed and fresh ore feedrate.

The stabilizing strategy was simulated by considering a constant particle size

distribution and a ratio between water flowrate and ore feedrate of 76% as well as a

change of 30% in ore hardness at time 250 minutes. Figure 5.18 shows the response

Search WWH ::

Custom Search