Environmental Engineering Reference

In-Depth Information

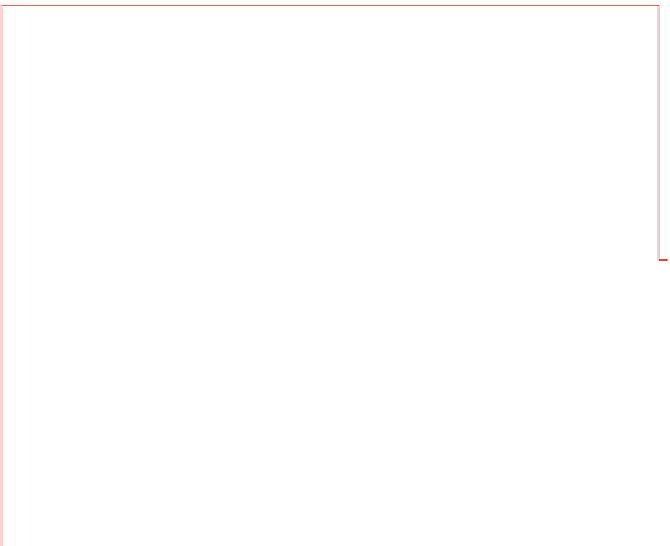

The basic phenomenological model for a classical grinding circuit as depicted

in Figure 5.10 consists of a rod mill model, a ball mill model, a sump model and

pump-cyclone models.

M

T

M

T

2

PSM

Step1

particle size distribution

LC1

0.5376

LC4

HYDROCYCLONE

WF2

W

BALL MILL

Mmi

MIX WMmi1

ROD MILL

MIX PP1

Step2

MF1

LC2

WF3

DT1

100

MIX WP1

DT

density

mass flow

M

T

MT

SUMP

level

PID

50

PUMP1

ciculating load

% Solids

pump

density

noise1

noise2

Time

u1

u2

circulating load

%Solids

Automatic control

Figure 5.10

Block diagram of a conventional grinding circuit

The grinding process is represented by a multiple-input multiple-output (MIMO)

system for which the following control inputs are considered:

1. water addition to the sump box (

u

1

);

2. fresh ore feedrate to the rod mill (

u

2

);

3. pump speed (

u

3

).

The outputs are:

1. product fineness (

y

1

);

2. circulating load (

y

2

);

3. sump level (

y

3

).

Water addition to the rod mill is a constant fraction of the fresh ore feedrate

(m

3

/

h of water = ton/h of fresh ore/1.86) [24]. Sump box level is regulated with a

Search WWH ::

Custom Search