Environmental Engineering Reference

In-Depth Information

mum of

T

2

da

mi

Γ

i

[

S

1

(

a

,

Γ

)−

V

1

(

a

,

Γ

i

)]

.

(4.149)

0

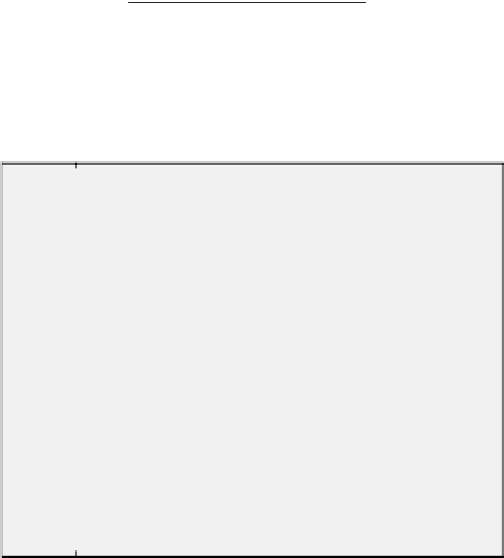

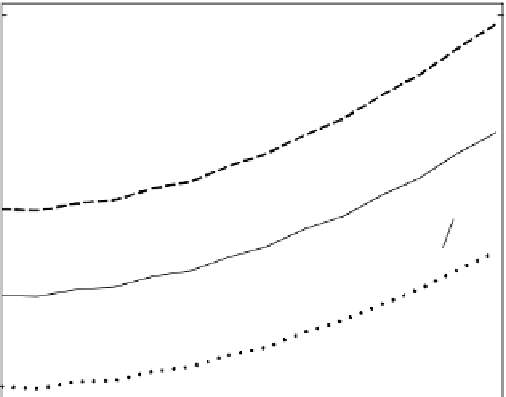

For example, in Figure 4.27 the estimated grindability corresponds to medium

ore.

1450

1400

1350

1300

Soft ore template

1250

Sample variance template

1200

Medium ore template

1150

Hard ore template

1100

4

6

8

10

12

14

scale a

(

,

)

Figure 4.27

Templates of CWT variance corresponding to feed ore

F

f

for hard ore and coarse

particle size, for medium ore and normal particle size, and for soft ore and fine particle size, under

normal operating conditions. Also shown is sample variance template

S

1

t

Γ

i

corre-

sponding to a given measurement when the ore grindability in the mill is medium, but unknown

(

a

,

Γ

)

for

F

f

(

t

,

Γ

)

Again, since probability functions are not known, expected values and variances

are computed using time averaged estimators (see Sections 4.2.2 and 4.3.2).

In order to proceed with the process of identifying Γ all templates are converted

into points in a Euclidean space of dimension

M

through discretizing the range of

scale

a

into

M

discrete values

{

a

1

,

a

2

,

a

3

,,

a

M

}

for each template; Figure 4.28 gives

a pictorial view of this conversion.

Further processing includes (i) Concatenation [22] of the three templates corre-

sponding to feed ore flow

F

f

(

t

,

Γ

i

)

,topowerdraw

P

d

(

t

,

Γ

i

)

, and to return ore flow

F

r

and of the sample templates; (ii) PCA to reduce dimensions while retain-

ing relevant information; and (iii) projection to Fisher space for further dimension

reduction and facilitating discrimination between the three possible grindability in-

dexes [22]. Concatenation is a juxtaposition of the templates, so it increases the

Euclidean space dimension from

M

(

t

,

Γ

i

)

42, but this dimension is brought

down to 8 using PCA, and may be further reduced to 2 by projection into the Fisher

space [57]. Figure 4.28 has an equivalence in the PCA space and in the Fisher space.

=

14 to 3

M

=

Search WWH ::

Custom Search