Information Technology Reference

In-Depth Information

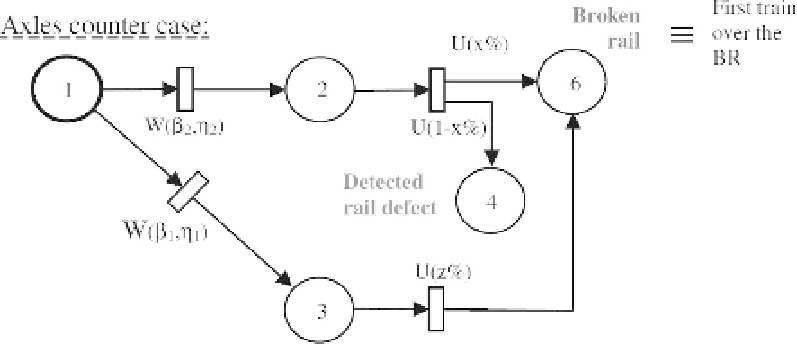

Fig. 6. The functions

h

(

t

)

, the renewal density of grindable and non grindable rail

defect

We assume that the rail defect and the associated derailment risk is a

dominant factor for the choice of the track inoccupancy and track integrity

detectors.

5

Conclusions

Each technology of TC or AC has its own domain of pertinence. Neither

should be rejected out of hand. In the current state-of-the-art, neither of

the two solutions allowing detecting the presence of trains is perfectly safe;

signalling plant implicitly integrates the possibility of transient failures of the

chosen solution.

The TC, through its occupancy detection function, provides, especially on

high tra

c or high speed lines, a higher level of safety because of lower risks

from human inter-vention, as much in maintenance, particularly corrective

maintenance, as in degraded mode operation. Moreover, it ensures a continual

check of the electrical integrity of the track. The TC's reliability is all the

better when the trac is great and/or that the traction system is electric

(typically

10

−

7

/h/TC on HSL). Moreover, the TC is well suited to trac

increase, since it allows the block to be permissive and sectional release in

signal boxes. With the TC's, the safety level isn't coupled with the track

maintenance policy, in particular regarding grinding.

The AC provides, in France, for low-trac lines, an economical solution to

the con-trol of clearing of long sections, without the risk of deshunting, albeit

at the price of a stricter route locking (absolute block, no sectional release

and so on) and greater operating complexity, in the event of disturbance or

failure. The rate of failure internal rail defect rate is particularly low in this

case.

The preventive grinding has been proven to minimise rail defects, to ex-

tend rail service life, to reduce the maintenance costs of the track but cannot