Information Technology Reference

In-Depth Information

In case of an alarm, one infrastructure manager has to inform the driver

of a train that a wayside hot box detection system has recognized a temper-

ature exceeding a warning limit. It is also possible to declare two limits of

temperature for warning and for triggering an alarm. In both cases an inspec-

tion of the axle is needed. This will be done by technical inspectors where

available or by the driver of the train. Important for the braking process is

the normal use of brake power and to prevent an emergency brake because

the forces involved could cause a derailment.

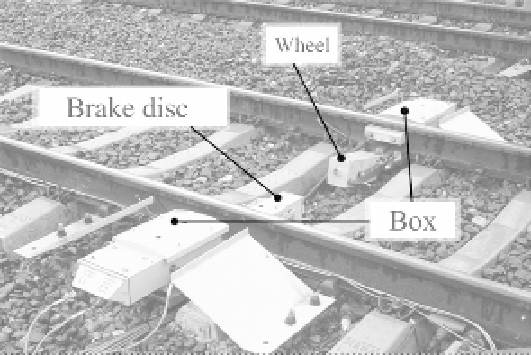

Fig. 1. Hot box and hot brake detection system used by Austrian Railways (ÖBB)

Staff (train driver, station inspector or wagon examiner) can only ascer-

tain visually if an axle journal is broken, an axle-bearing is glowing, or an

axle-box case is deformed. Even if none of these indicators can be found,

the train will continue its journey with reduced maximum speed to the next

place where a technical inspector is available. Otherwise - if the driver veri-

fies the defect - the wagon has to be removed even when the alarm has been

generated by the locomotive itself.

Because of the early development of hot box detectors national standards

were mainly used for their design. In accordance to the current standards

of CENELEC [3] the question arises if such systems have to fulfill certain

safety requirements (by means of a tolerable hazard rate and safety integrity

level). For a rough estimation of the recommended safety requirement, the so

called Best Practice Risk (BP-Risk) analysis offers a suitable methodology

to answer this question.