Information Technology Reference

In-Depth Information

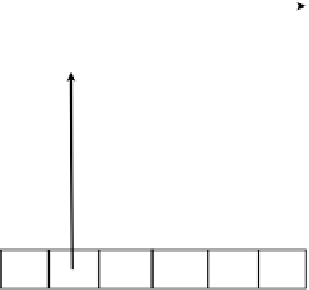

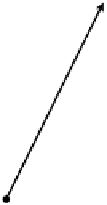

movement direction

Assembly

y

x

Feeder Magazine

movement direction

Fig. 2.5.

Robot movement

move in shortest possible path (i.e. always tries to move in vertical direction) if vertical

movement is not possible than it needs to stretch/compress its arm to avoid tardiness.

This section reveals the formulation of DPP problem statement using the following

notations:

V

a

speed of assembly arm

V

b

speed of board

V

¬

m

speed of magazine

N

number of placement components

K

number of component types (

K

≤

N

)

i

th

placement in a placement sequence

b

(

i

)

i

th

placement in a pick sequence

m

(

i

)

x

i

+1

=

M

i

+1

+

M

i

+1

interception distance of

robot arm

and

magzine

x

i

+1

=

B

i

+1

+

B

i

+1

interception distance of

robot arm

and

board

T

(

m

(

i

)

,

b

(

i

))

robot arm travel time from magazine loca-

tion

m

(

i

) to board location

m

(

i

).

T

(

b

(

i

)

,

b

(

i

))

robot arm travel time from board location

b

(

i

) to magazine location

m

(

i

).

Tplace

time taken to place the component

Tpick

time taken to pick the component

CT

total assembly time

Fig 2.6 shows possible movements of board and magazine in DPP model [19]. Sup-

pose the robot arm has finished placing the

i

th

component at point

B(i)

then moves to

pick the next (

i

+ 1)

th

component from slot

M(i+1)

on the magazine. If magazine is able

to travel distance

d

(

a

,

c

)=

||

a

−

c

||

before the robot actually arrives vertically towards

Search WWH ::

Custom Search