Environmental Engineering Reference

In-Depth Information

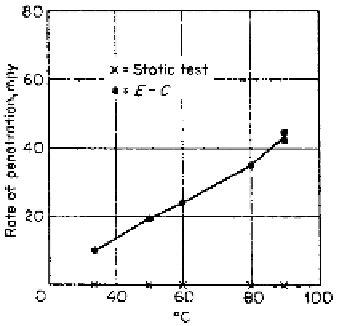

Figure 3.29

Erosion corrosion of lead by 10% sulfuric acid flowing at 39 ft/s. Cross-

marks (*) on abssica indicate the results of tests in static medium.

3.8.2 Metallurgical Factors

Soft and low-strength metals like copper, aluminum, and lead are especially sus-

ceptible to erosion corrosion. So are the metals and alloys that are inherently less

corrosion-resistant, like carbon steels.

Stainless steels of all grades are, in general, resistant to erosion corrosion and

their performance improves with increasing nickel, chromium, and addition of

molybdenum. In iron-chromium alloys of lower grades, the resistance progres-

sively increases with increase in chromium content. Stainless steels and chro-

mium steels are resistant because of their tenacious protective surface films. In

other alloy systems also, development of a more stable protective film improves

their resistance to erosion corrosion, e.g., addition of iron to cupronickels or alu-

minum to brasses.

As a rule, solid solution alloys provide better resistance than alloys hardened

by heat treatment because the latter are heterogeneous in structure.

Cast irons usually perform better than steel. Alloy cast irons containing nickel

and chromium show better performance. Durinon, containing 14.5% Si, gives

excellent performance under severe erosion corrosion conditions.

3.8.3 Remedial Measures

Improvement in Design

Erosion corrosion can be minimized or eliminated altogether by change of design,

i.e., the shape and geometry of the components, and also by increasing the wall