Environmental Engineering Reference

In-Depth Information

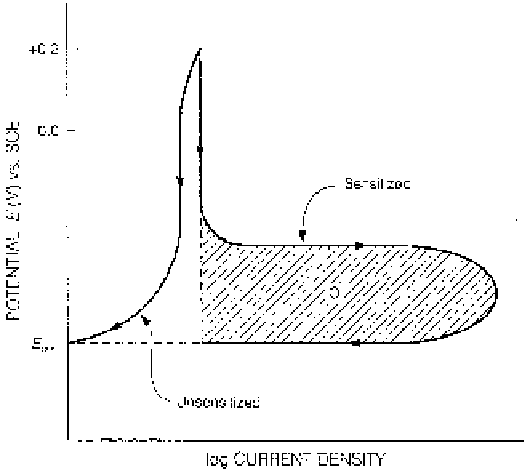

Figure 3.21

Schematic representation of procedure for electrochemical potentioki-

netic reactivation (EPR) study to determine sensitization.

denum carbide causes molybdenum depletion and susceptibility to intergranular

attack in hot reducing acids as well as in HNO

3

. Reduction of carbon and silicon

has imparted improved resistance. Hastelloy B and C become susceptible when

heated in the range of 500-705

C in which immunity can be restored by suitable

heat treatment at higher temperatures (1150-1240

°

C).

Copper alloy 260 (70-30 brass) corrodes intergranularly in dilute aqueous

solutions of H

2

SO

4

,Fe

2

(SO

4

), BiCl

3

, and other electrolytes. Enrichment of grain

boundary region in zinc through segregation is considered to be the cause of

attack.

Segregated iron at the grain boundary makes the high-purity aluminum suscep-

tible to intergranular corrosion. The precipitated phases in the high-strength

alloys are the cause for intergranular attack. For example, CuAl

2

precipitation in

Duralumin-type alloys causes copper depletion and a substantial potential differ-

ence is set up between the depleted area and the adjacent material. In 5000 and

7000 series alloys, precipitated phases like FeAl

3

,Mg

5

Al

8

, MgZn

2

, etc., at the

grain boundary are anodic with respect to the grain matrix. Solution heat treat-

ment eliminates the susceptibility to intergranular corrosion at the cost of loss

in strength. Attack along the boundaries of grains elongated in the rolling direc-

°