Environmental Engineering Reference

In-Depth Information

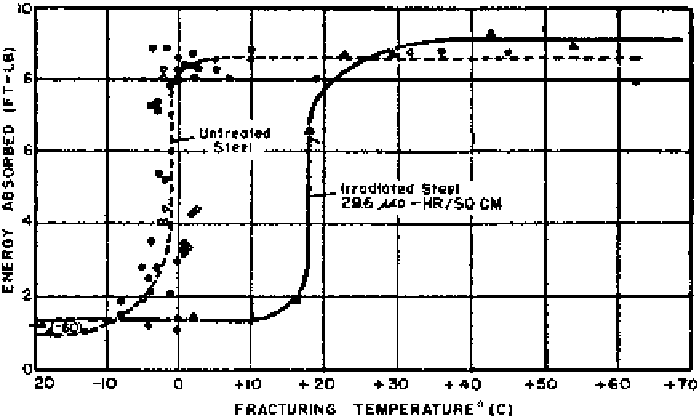

Figure 9.11

Transition curves for unirradiated and irradiated impact specimens of

mild steel, Ref. 23.

Figure 9.11 shows the results obtained in impact tests before and after irradiation

with 18.6 MeV deuterons for an average total exposure of 6.7

10

17

particles/

cm

2

[26]. The transition temperature has changed from

1

°

C to about 8

°

C. Simi-

larly, in molybdenum, an increase from

30

°

Cto70

°

C has been reported [27].

9.6.1 Mechanism

Irradiation strengthening of metals is a result of the barriers to dislocation motion

that are produced from precipitation of radiation-induced defects, i.e., vacancies

and interstitials. The barriers formed are voids and dislocation loops. In some

alloy systems, such as nickel alloys and stainless steels, irradiation-induced pre-

cipitation of second phases such as carbides may also contribute to the observed

strength increase. While the pinning of dislocations directly contributes to the

increase in yield stress, the critical shear stress also increases because it depends

on the breakaway of pinned dislocations.

The controlling factor in the effects of irradiation on deformation behavior is

the irradiation-produced microstructure, which is temperature-dependent. It has

been demonstrated that [28]

1.

At low irradiation temperatures (below 0.35

T

m

), irradiation-produced vacan-

cies and interstitials collect into small dislocation loops.