Environmental Engineering Reference

In-Depth Information

Most often, the fracture occurs at sustained loads below the yield strength of

the material. The fracture time increases as the load is decreased. The applied

stress versus the fracture time plots resemble similar plots obtained in SCC or

liquid metal embrittlement. Like the fatigue S-N curve, a threshold stress exists

below which HSC does not occur. This threshold stress is a function of the

strength level of the steel and the specific hydrogen-bearing environment. Gener-

ally, the threshold stress decreases as the yield strength and tensile strength of

the material increase. Lower strength alloys below a minimum tensile strength

are not usually affected. In ferrous alloys, HSC is generally restricted to those

alloys having a hardness of 22 HRC or greater. The sensitivity increases with

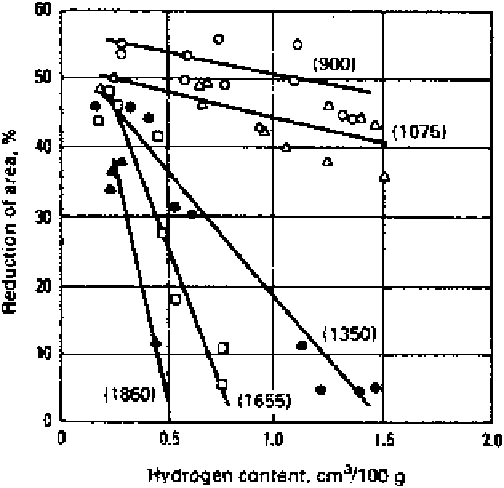

the increase in strength level, as shown in Fig. 8.3.

A predominant feature of HSC is that the occurrence of the fracture is delayed,

which implies that hydrogen diffusion in the metal lattice is important for the

building up of sufficient hydrogen concentration at the regions of triaxial stresses

for crack nucleation or at the crack tip for its propagation. The susceptibility to

cracking, therefore, depends on the kinetic factors, such as hydrogen gas pressure

and temperature, which influence the diffusion process. Increasing the hydrogen

pressure reduces the threshold stress intensity for crack preparation and increases

Figure 8.3

Ductility versus hydrogen content for quenched and tempered steels at vari-

ous strength levels. Figures in parentheses indicate the ultimate tensile strength in MPa [21].