Environmental Engineering Reference

In-Depth Information

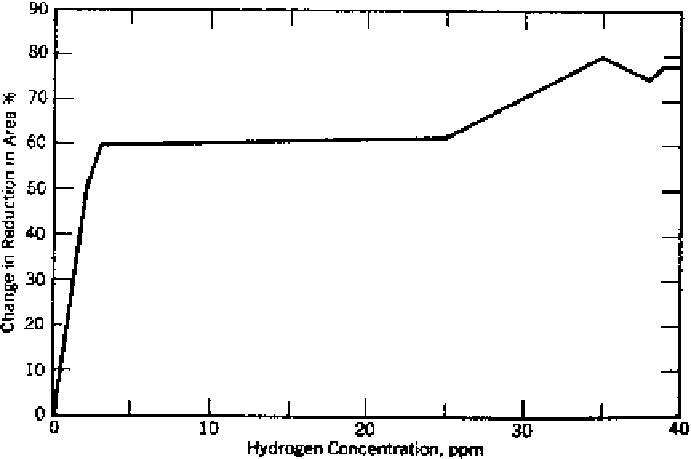

Figure 8.1

Loss of ductility in steel as a function of hydrogen content [23].

This type of damage is most often observed in lower strength alloys and has

been encountered in steels, stainless steels, nickel-base alloys, aluminum alloys,

and titanium alloys exposed to hydrogen. Figure 8.2 shows the ductility loss for

several austenitic stainless steels in high-pressure hydrogen. A wide variation in

hydrogen damage in these alloys is apparent. Type 304L is most susceptible and

the stable austenitic alloys, such as 15Cr-25Ni, are minimally affected.

The loss of ductility is temporary and can be reversed by the driving out of

hydrogen from the metal. This is accomplished by heating the metal. The rate

of recovery depends on time and temperature; lower is the time required at higher

temperatures. However, heating above 315

C is not usually recommended due

to the risk of high-temperature hydrogen attack.

°

Hydrogen Stress Cracking

Hydrogen stress cracking (HSC) refers to the brittle fracture of a normally ductile

alloy under sustained load in the presence of hydrogen. This type of damage has

been encountered in carbon and low-alloy steels, stainless steels, nickel alloys,

and aluminum alloys. HSC has been studied most extensively in steels and has

been described by various other names, i.e., hydrogen-induced cracking (HIC),

hydrogen-assisted cracking (HAC), delayed failure, and static fatigue. The cata-