Environmental Engineering Reference

In-Depth Information

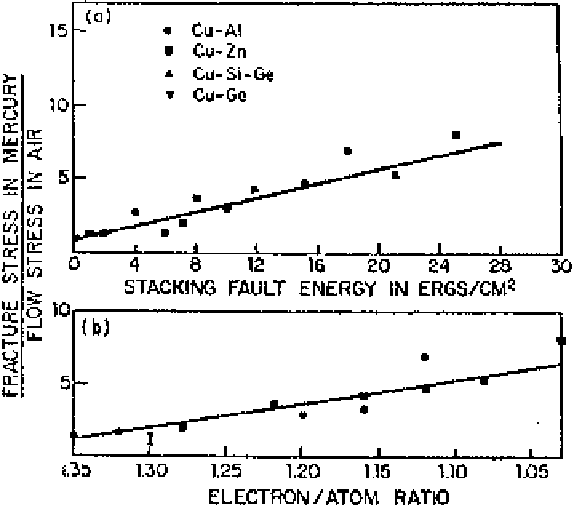

with the susceptibility to LME for some alloy systems. For example, in copper

alloys (alloyed with Al, Si, Zn, or Ge) the ratio of fracture stress in mercury to

flow stress in air,

σ

Y

, has been shown to decrease progressively with increase

in yield stress; at the same time this ratio increases linearly with increasing energy

over the range 0-25 ergs, as well as with the increasing electron/atom ratio in

these alloys (Fig. 7.9).

In iron, a nickel addition of more than 8% gives rise to martensite with coarse

slip lines. In precipitation-hardening aluminum and copper alloys, maximum sus-

ceptibility to LME coincides with the peak strength of the alloys. All of these

point to the generation of stress concentrators as a result of alloying. It is interest-

ing to note that precracked or notched samples of iron-nickel alloys having 2-

8% Ni are readily embrittled in mercury.

σ

F

/

Effect of Solute Additions to the Liquid Metal

It can be seen in Fig. 7.1 that the progressive addition of lead to liquid bismuth

reduces the embrittlement of copper [5]. Similar effects have been reported for

additions of Sb, Cd, Tl, or Zn. Several minor additions have been made to mer-

Figure 7.9

Embrittlement of copper alloys as a function of stacking-fault energy and

electron/atom ratio. (After Stoloff et al. [5].)