Environmental Engineering Reference

In-Depth Information

7.2.2 Factors Influencing LME

Effect of Grain Size

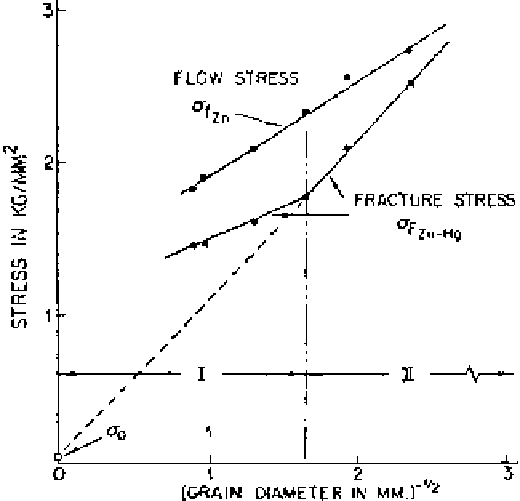

The yield stress and the fracture stress of a metallic material normally bear a

linear relationship with the inverse square root of grain diameter, which is known

as the Hall-Petch relationship:

σ

σ

1

kd

1/2

where

σ

yield stress or fracture stress

d

grain diameter

constants

The same relationship holds true for LME as well. A linear decrease of fracture

strength as a function of

d

1/2

, where

d

is the average grain diameter, has been

observed for copper and iron in molten lithium, 70-30 brass in mercury, and

zinc in mercury, indicating that coarser grained materials are more susceptible

to LME. Figure 7.6 shows the variation of flow and fracture stresses of amalgam-

d

i

,

k

Figure 7.6

Variation of flow and fracture stresses of amalgamated zinc specimens

with grain size at 25

°

C [8].