Environmental Engineering Reference

In-Depth Information

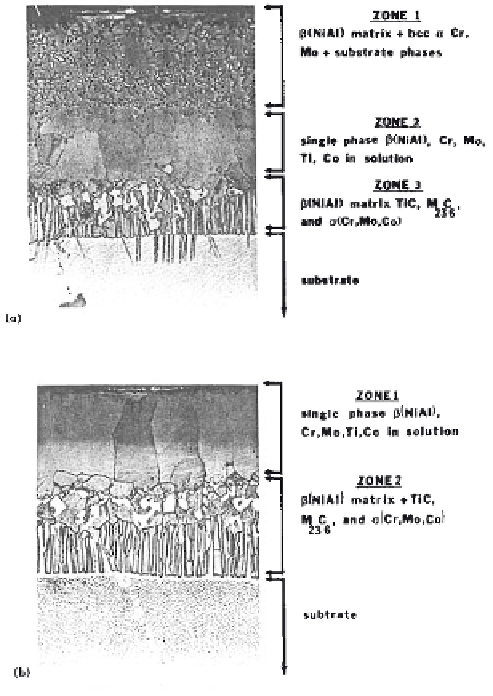

Figure 6.51

Typical aluminide coating microstructures formed on U-700 by (a) high-

activity process and (b) low-activity process. Magnification 1000

, both parts reduced

to 50% for reproduction [71].

ings are generally tailor-made for a given alloy composition. Significant improve-

ments in the oxidation and hot corrosion resistance of aluminide coatings can be

achieved by predepositing of a noble metal, specifically platinum and/or rhodium.

The noble metal is generally electroplated as a thin (0.40

m) layer before the

aluminizing process. In the low-activity process for nickel-based superalloys, to

avoid the deleterious effect of titanium, which is often present in the alloy, a

suitable predeposit of titanium-free Ni-based alloy is often recommended to trap

Ti in the form of Ti(C,N). Similarly, in a high-activity process, predeposit of a

µ