Environmental Engineering Reference

In-Depth Information

6.7.2 Kinetics

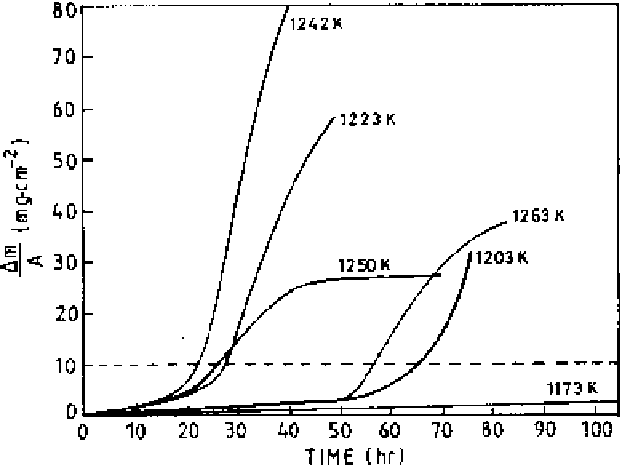

Several authors have suggested that hot corrosion of all susceptible alloys and

coatings is characterized by a two-stage process: an incubation period with a

slow rate of reaction, possibly with the alloy being protected by a stable Cr

2

O

3

or Al

2

O

3

layer; and a propagation stage with rapid and often catastrophic material

degradation as illustrated in Fig. 6.32. During the incubation period, elements in

the alloy are oxidized, and electrons are considered to be transferred from metallic

atoms to reducible substances in the salt deposit. When the reduced substances

are the same as those that would have reacted with the alloy in the absence of

the deposit, the reaction product barrier forms beneath the salt on the alloy sur-

face. As the hot corrosion process is continued, certain features become apparent

which indicate that the salt is affecting the corrosion process, and eventually the

selective oxidation process is ineffective. The time, which may vary from a few

hours to thousands of hours for which the most effective reaction product barrier

is stable beneath the salt layer, is influenced by a number of factors as illustrated

in Fig. 6.33. These factors include alloy composition and its microstructure, fabri-

cation condition, pretreatment of alloys, environment composition, gas velocity,

erosion, salt deposit condition and its composition, performance/test temperature,

Figure 6.32

Mass change versus time for IN-738 alloy coated with 1 mg/cm

2

Na

2

SO

4

in 1 atm O

2

at different temperatures [16].