Environmental Engineering Reference

In-Depth Information

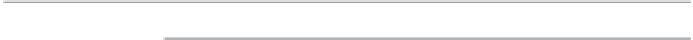

Table 6.5

Compositions of Cobalt-Based Superalloys

Composition in wt.% (balance Co)

Cr

Ni

Fe

Mo

W

Ti

Cb

C

Others

I. Wrought alloys

S 816

20

20

4

4

4

—

4

0.38

—

HA 188

22

22

1.5

—

14

—

—

0.1

0.08 La

L 605

20

10

—

—

15

—

—

0.1

—

Mar M 918

20

20

—

—

—

—

—

0.05

7.5 Ta, 0.1 Zr

II. Cast alloys

HS 21

27

3

1

5

—

—

—

0.25

—

X 40

25.5

10.5

2

—

7.5

—

—

0.5

0.01 B

FSX 414

29.5

10.5

2

—

7

—

—

0.35

0.01 B

Mar M 509

24

10

—

—

7

0.2

—

0.6

3.5 Ta, 0.5 Zr

Mar M 302

21.5

—

—

—

10

—

—

0.85

9 Ta, B, Zr

Source

: R. W. Cahn, P. Haasen, and E. J. Kramer, eds.

Materials Science and Technology

, Vol. 7.

VCH, Weinheim, 1992, p. 685.

for which the present discussion is limited to either pure Ni or Co or their respec-

tive alloys.

It is to be further recognized that once a deposit of Na

2

SO

4

has been formed on

the alloy surface, the extent to which the deposit affects the corrosion resistance of

the alloy will be governed by whether or not the deposit melts at the operating

temperature, how adherent it is, and the extent to which it wets the surface. Even

though a liquid deposit is generally necessary for severe hot corrosion to occur,

considerable degradation of alloys and oxidation-resistant coatings in marine gas

turbines has also been experienced under dense, thick, solid deposits. Accord-

ingly, hot corrosion processes have been subdivided into two categories: type I,

high-temperature hot corrosion (HTHC) processes, which are experienced above

the melting temperature of pure Na

2

SO

4

(1157 K), and type II, low-temperature

hot corrosion (LTHC) processes, which occur at temperatures below the melting

point of Na

2

SO

4

(i.e., in the range 873-973 K) where the deposited salt is ex-

pected to be solid [56]. The combustion gases arising from burning of coal and

other types of fuel oil contain both SO

2

and SO

3

; accordingly, to simulate the

service environmental conditions, most of the hot corrosion tests employ either

static air or flowing oxygen

SO

2

gas mixtures over a platinum catalyst, and/

or SO

3

, since SO

2

1

/

2

O

2

s SO

3

.SO

2

or a mixture of SO

2

O

2

and/or SO

3

contains two oxidants, S and O. If one considers the thermodynamic equilibrium

between a metal and a mixture of SO

2

O

2

, only one stable compound, e.g., an

oxide or a sulfate, is the stable end product of the reaction. However, for kinetic