Environmental Engineering Reference

In-Depth Information

oxide-oxygen interface to the oxide-metal interface as often experimentally

observed.

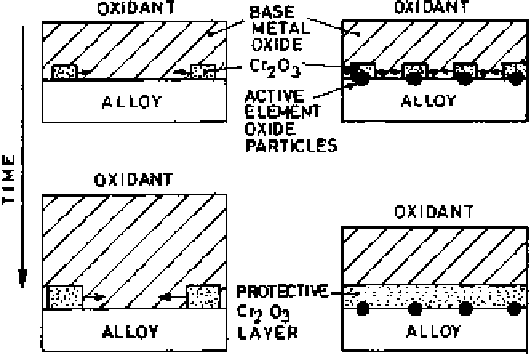

Of the three mechanisms proposed above to explain the role of active elements,

the doping effect and the formation of a diffusion barrier layer lack general appli-

cability. The most probable mechanism is the third, where it is proposed that the

dispersed active element oxide particles at the alloy surface act as heterogeneous

nucleation sites for the first formed oxides, thereby decreasing the internuclei

spacings. As a consequence, less time will be required for subsequent lateral

growth processes to link the nuclei to form a protective Cr

2

O

3

scale, as illustrated

schematically in Fig. 6.24.

Subsequent analytical electron microscopic (AEM), energy dispersive X-ray

analysis (EDX), and microdiffraction studies [43], in establishing the composi-

tion and structure of YCrO

3

particles formed by Y

2

O

3

-Cr

2

O

3

solid solution reac-

tion, revealed that the Y

2

O

3

and YCrO

3

particles acted as the sources of Y

3

ions

that segregated along the oxide grain boundaries in the scale formed on Ni-20%

Cr-0.6% Y

2

O

3

alloy, Y-implanted Fe-20% Cr-25% Ni stainless steel and Y-im-

planted chromium. Such observations prompted researchers to conclude that inhi-

bition of transport along the dominant grain boundary pathways by reactive ele-

ment segregants limits the oxide growth by cation diffusion. The reactive element

oxide particles act as sources for the segregants in the scale. As an extension of

this model, Pint [51] suggested the ''dynamic segregation theory,'' which states

that all of the reactive element effects in Cr

2

O

3

and Al

2

O

3

scale-forming alloy

Figure 6.24

Schematic illustration of the role of reactive element oxide particles in

an alloy surface acting as heterogeneous sites for Cr

2

O

3

nucleation and facilitating lateral

growth processes to form a protective layer.