Environmental Engineering Reference

In-Depth Information

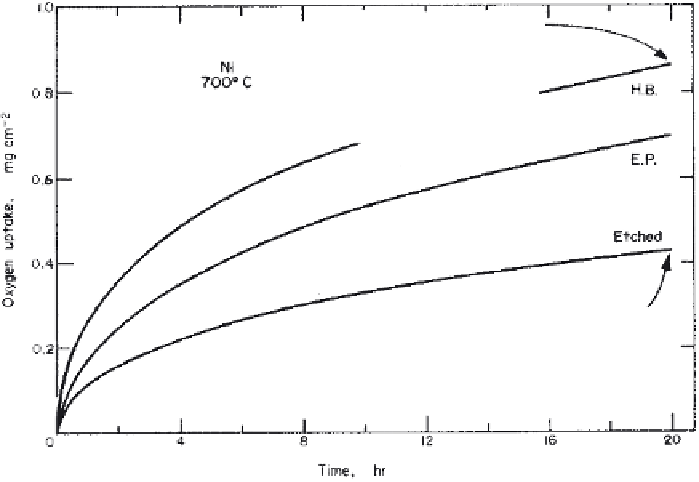

Figure 5.36

Effect of surface pretreatment on the kinetics of oxidation of polycrystal-

line Ni at 700°C and 0.5 torr O

2

pressure. Scanning electron micrographs of the outer

surface of the oxides illustrate a uniform fine-grained oxide on H. B. (''hot-bare'') Ni

compared with a marked variation in oxide thickness with substrate orientation on ''fur-

nace-raised'' ETCHED Ni [Ref. 64].

0.5 torr,

demonstrating the effect of oxidation procedures and surface pretreatments. It

clearly depicts how substrate orientation affects oxide grain size and oxidation

rate. Similar to observations at 973 K, the HB specimen exhibits the fastest oxida-

tion; however, EP Ni is found to oxidize at a slower rate than ETCHED Ni,

contrary to the results at 973 K. After about 40 min exposure, however, an en-

hanced rate of oxidation is observed for EP Ni. At greater oxide thickness,

ETCHED Ni undergoes oxidation at a relatively slower rate consistent with the

results as shown in Fig. 5.36.

On polycrystalline Ni, the kinetic data represent an average oxidation rate of

different substrate orientations. Experimentation on a single crystal hemisphere

shows that orientations close to (112) after EP oxidizes at a much reduced rate,

where only

Figure 5.37 shows the early stages of Ni oxidation at 873 K in

P

O

2

10 nm of oxide film is formed in 1 h. Reflection electron diffraction

has established the oxide to be single crystal [(111) antiparallel NiO on (111)

steps of the (112) macrosurfaces], and its low growth rate is a consequence of the