Environmental Engineering Reference

In-Depth Information

Mechanism

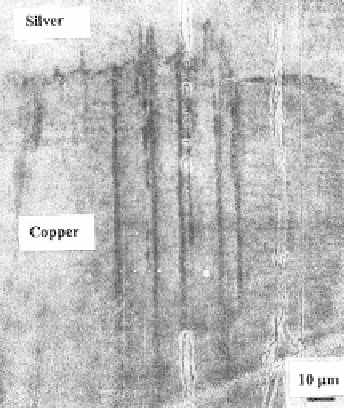

In mechanical fatigue, the crack initiation is attributed to the formation of extru-

sions and intrusions at the metal surface because of localized slip within the grain

caused by the stress (Fig. 3.59). The slip is localized because the stress is not

large enough to produce massive slip. Once the crack initiates the tip of the

crack undergoes localized plastic deformation in the same manner and the crack

propagates. Stresses below the endurance limit cannot overcome the work harden-

ing caused by plastic deformation and further slip is impeded.

Since corrosion fatigue involves the lowering of endurance limit or the change

of the fatigue behavior of ferrous metals to that of nonferrous metals exhibiting

no endurance limit, it has been envisaged that the corrosive environment helps

in the process of localized plastic deformation at the crack tip. This may be

achieved either by the removal of the barriers to plastic deformation, such as

dislocation piled up at the metal surface at slip steps, or by favoring plastic defor-

mation by the reduction of surface energy. The process of formation of extrusions

and intrusions thus continues at lower stress levels.

Although the exact mechanism has not been quantitatively presented, it never-

theless explains the combined role of stress and corrosion. The more aggressive

the solution, the more of this effect is achieved. Also, the shortening of fatigue

life with the application of cyclic stresses of lower frequency is explained by the

Figure 3.59

Extrusions and intrusions in copper after 6

10

5

cycles in air silver-

coated after test.