Environmental Engineering Reference

In-Depth Information

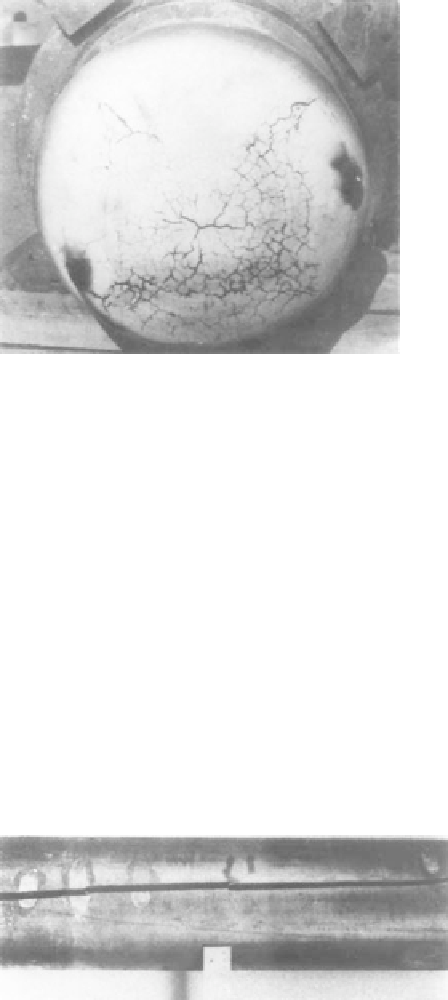

Figure 3.53

Stress corrosion cracking of type 304 stainless steel autoclave due to

chloride contamination.

steel [7]. The failure in service took place in a matter of hours and was traced

to the buildup of chloride concentration on the outside surface because of evapo-

ration of the water used for cooling, which originally contained only a negligible

amount of chloride. Yet another interesting example of SCC is depicted in Fig.

3.54, where the development of longitudinal cracks in a cold-drawn brass tube

had its origin at the bird droppings that provided the ammonia necessary for

corrosion [9]. The occurrence of SCC has been reported in high-strength alumi-

num alloy components in low-flying British military aircrafts arising from chlo-

ride-contaminated moisture, which led to the ban on the use of the material until

a solution was found through cladding of the material with pure aluminum. Car-

bonate-bicarbonate environments have been identified as the probable cause of

cracking in natural gas transmission steel pipelines [48].

Figure 3.54

Stress corrosion cracking of cold-drawn 70-30 brass tube originating at

bird droppings.