Environmental Engineering Reference

In-Depth Information

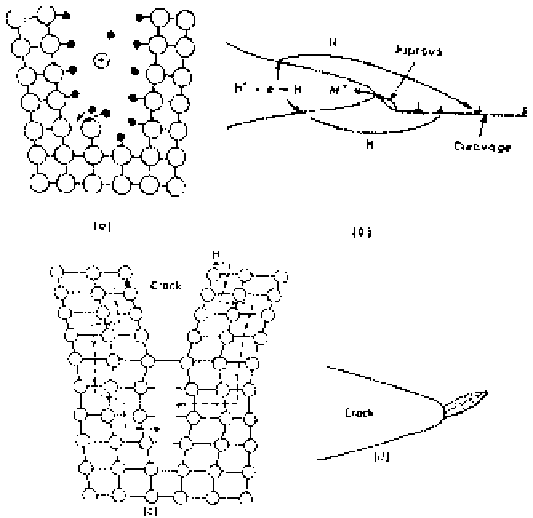

Figure 3.49

Hydrogen-assisted cracking mechanisms. (a) Crack tip adsorption and

bond rupture. (b) Embrittlement due to anchoring of dislocations by adsorbed hydrogen.

(c) Decohesion by hydrogen influx to dilated lattice. (d) Crack extension due to brittle

hydride phase formation.

SCC in these alloys. Again, all of the environments and conditions in which SCC

is encountered do not produce hydrogen, and some of them produce surface films

that constitute an effective barrier to hydrogen entry. These restrict the universal

applicability of hydrogen-induced cracking as an SCC mechanism.

The adsorption-induced cleavage

mechanism, or the stress-sorption cracking

mechanism [32], is based on the hypothesis that adsorption of environmental

species lowers the interatomic bond strength and the stress required for cleavage

fracture—an idea similar to the decohesion model of hydrogen-induced cracking.

Adsorption is assumed to be potential-dependent, which accounts for the stoppage

of SCC by cathodic polarization below a critical potential. The specificity of the

species for inducing SCC in a particular alloy can also be conveniently explained

in terms of preferential adsorption. However, this model does not explain how

the crack maintains an atomically sharp tip in a normally ductile material, and

it also fails to explain the discontinuous nature of crack propagation.

The tarnish rupture mechanism

was originally proposed to explain discontinu-