Environmental Engineering Reference

In-Depth Information

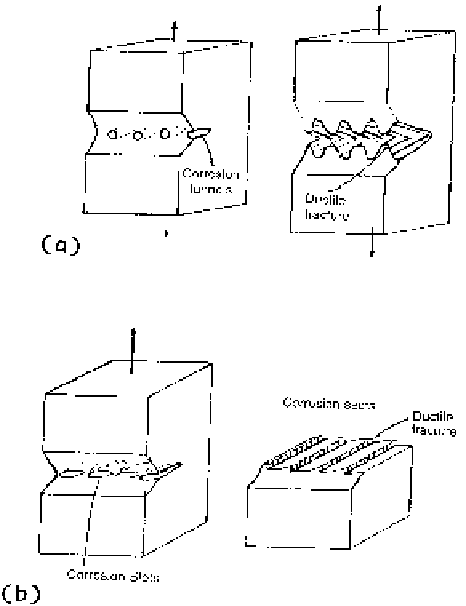

Figure 3.48

Corrosion tunnel models. (a) Initiation of a crack by the formation of

corrosion tunnels at slip steps and ductile deformation and fracture of ligaments. (b) Disso-

lution of tunnels to flat-slot formation.

of hydride then forms in the region of crack tip and the process is repeated,

resulting in discontinuous crack growth.

Hydrogen-assisted crack growth in the manner described above has been sug-

gested as the SCC mechanism for ferritic steels, nickel-base alloys, austenitic

stainless steels, aluminum alloys, and intermetallic compounds. The most proba-

ble source for atomic hydrogen to enter the metal is the cathodic reduction of

hydrogen ions accompanying anodic dissolution in aqueous environments. Mate-

rials with impurities like sulfur, phosphorus, antimony, and tin segregated at grain

boundaries have been found to be more susceptible to hydrogen-induced cracking

because these impurities act as hydrogen evolution poisons. On the other hand,

the growing stress corrosion cracks have been effectively stopped in low-strength

ductile alloys by cathodic polarization, refuting the validity of hydrogen-assisted