Environmental Engineering Reference

In-Depth Information

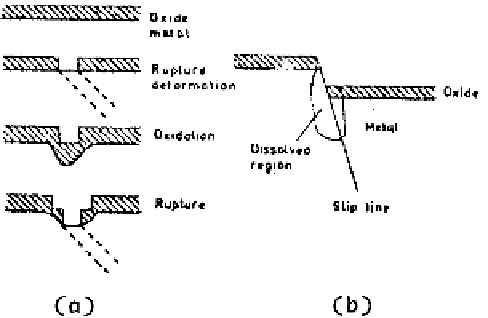

Figure 3.47

Strain-generated active path mechanisms. (a) Film rupture model. (b)

Slip-step dissolution model.

a change in the morphology of corrosion damage from tunnels to thin, flat slots,

as shown in Fig. 3.48b. The width of the corrosion slots has been shown to

approach atomic dimensions and a close correspondence of matching surfaces is

expected.

Cleavage Mechanisms.

Several mechanisms have been postulated to explain

the cleavage-type cracking encountered in SCC. These are hydrogen-assisted

cracking, turnish rupture, film-induced cleavage, adsorption-induced cleavage,

and atomic surface mobility mechanisms.

Hydrogen-assisted cracking mechanism

is very often described by the surface

energy lowering model [30] in which atomically dissolved hydrogen acts to

weaken the interatomic bonds in the plain-strain region of the crack tip (Fig.

3.49) by lowering the surface energy

γ

s

in the Griffith equation:

σ

c

(2

E

γ

s

/

π

c

)

1/2

(3.7)

where

σ

c

is the fracture stress necessary to cause the propagation of an elliptical

crack of length 2

c

and

E

is Young's modulus. Blocked glide planes have been

considered to provide the initial Griffith cracks in steels. The decohesion may

also be caused by hydrogen influx to the dilated lattice [31]. It has also been

suggested that hydrogen decreases the stacking-fault energy to induce coplanar

deformation at the tip. Embrittlement would then result from Lomer-Cottrell

supersessile dislocations on the intersecting slip planes. The embrittlement has

also been ascribed to the stress-assisted formation of brittle hydride phase ahead

of the crack tip which facilitates crack growth by cleavage, with cracks arresting

at the boundary where the relatively tough matrix is encountered. Another particle