Environmental Engineering Reference

In-Depth Information

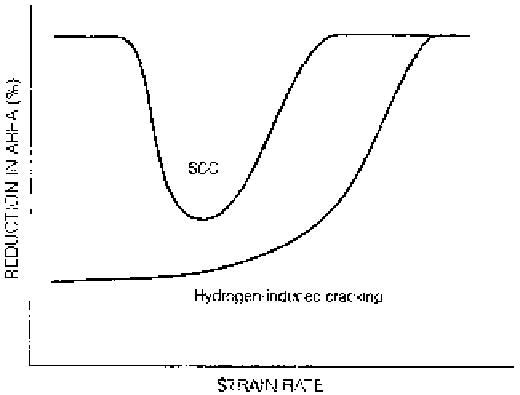

Figure 3.40

Schematic presentation of the effect of strain rate on SCC and hydrogen-

induced cracking.

constant load test methods in that the experiment can be completed in a short

time (2 days maximum) to ascertain the susceptibility to SCC in an alloy in a

given environment. However, the results may not be always indicative of SCC

in a similar environment in service where a forced, continuous strain is absent.

Metallurgical Aspects of SCC

Virtually all alloys are susceptible to SCC in the appropriate environments. Sus-

ceptibility to SCC is affected by the chemical composition of the alloy, size and

preferential orientation of grains, composition and distribution of precipitates,

dislocation interactions, and the progress of phase transformation. Bulk alloy

composition can affect passive film stability and phase distribution (e.g., chro-

mium in stainless steel), minor alloying elements can cause local changes in

passive film-forming elements (e.g., carbon in stainless steel causing sensitiza-

tion), impurity elements can segregate to grain boundaries and cause local differ-

ence in the corrosion rate (e.g., phosphorus in nickel or nickel-base alloys), and

inclusions can cause changes in the local crack-tip chemistry as the cracks inter-

sect them (e.g., manganese sulfide in steel).

The effect of bulk alloy composition on SCC susceptibility is best exemplified

in stainless steels and copper alloys. Figure 3.41 shows the effect of nickel content

on SCC in stainless steels exposed to boiling 42% magnesium chloride solution,

a common SCC medium used in the laboratory to simulate the cracking in hot