Environmental Engineering Reference

In-Depth Information

Schreier et al. (2006) performed a series of bench-scale studies assessing the viability of using

ozone alone for ISCO, as opposed to mixing ozone and hydrogen peroxide

in situ

, which can be

difi cult in heterogeneous aquifer materials. The work was performed in support of remedial action

at the Cooper Drum Superfund site in South Gate, Los Angeles County, California, where 1,4-dioxane

concentrations targeted for treatment by ISCO were as high as 750

g/L (Yunker, 2007). Peroxone,

the mixture of ozone and hydrogen peroxide, is a demonstrated oxidizer, as already described, but

ozone alone had been commonly regarded as not being of sufi cient oxidation potential to destroy

1,4-dioxane. Ozone sparging of site groundwater resulted in the complete removal of 1,4-dioxane.

To assess whether the removal was due to volatilization or destruction, vapor samples were col-

lected from the off-gas and a sparge with inert gas (nitrogen) was evaluated. The data indicate that

1,4-dioxane removal was due to oxidation. Schreier et al. postulated that naturally occurring inor-

ganic materials in the site soil or groundwater were enhancing the capability of ozone, which could

eliminate or reduce the need for hydrogen peroxide. Ferrous iron, chelated iron, bicarbonate, and

cocontaminants such as TCE were evaluated as potential oxidation enhancers. A test of spiked

deionized water indicated that ozone alone was capable of reducing concentrations from 400 to

98

μ

g/L. Additional tests run with ferrous iron, chelated

iron, and bicarbonate resulted in reductions down to the detection limit. 1,4-Dioxane removal in the

presence of TCE did not signii cantly differ from the removal observed with ozone alone. Schreier

et al. (2006) concluded that natural waters may contain elements or compounds that allow ozone to

succeed at complete 1,4-dioxane removal.

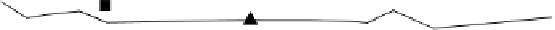

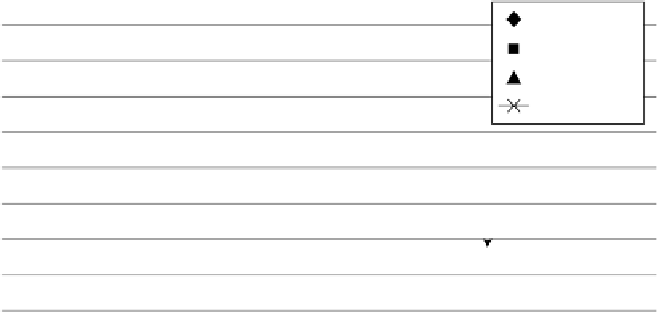

A follow-on i eld pilot study at the same site (Sadeghi et al., 2006; Sadeghi and Gruber, 2007;

USEPA, 2007) involved the use of specially constructed wells with an ozone diffuser in the bottom

of the well and a hydrogen peroxide diffuser higher in the well, such that the two amendments inter-

act in the subsurface to form the hydroxyl radical. This system is patented by Applied Process

Te ch nolog y a s t he P u lse - OX

TM

(Applied Process Technology, Inc., Pleasant Hill, CA) system. Initial

injections were of ozone alone, which resulted in signii cant reductions in 1,4-dioxane (and TCE)

concentrations (Figure 7.12). Five months later, hydrogen peroxide injections were initiated, and it

was determined that optimal results were achieved with the combination of 16% hydrogen peroxide

and 2 pounds per day per injection well or 1 pound per day per injection interval of ozone. The

μ

g/L, but not to the detection limit of 3

μ

1000

TCE

cis

900

-1, 2-DCE

1,1-DCA

1,4-Dioxane

800

O

3

700

increased

Focused

in

je

ction

600

End of

pilot test

500

400

300

200

100

0

-50

0

50

100

150

200

Days

250

300

350

400

450

FIGURE 7.12

ISCO i eld pilot study results. (From Sadeghi, V.M. and Gruber, D.J., 2007,

In situ

oxidation

of 1,4-dioxane with ozone and hydrogen peroxide. Poster presentation at URS's Environmental Technology

and Management Seminar, Oakland, CA.)

Search WWH ::

Custom Search