Environmental Engineering Reference

In-Depth Information

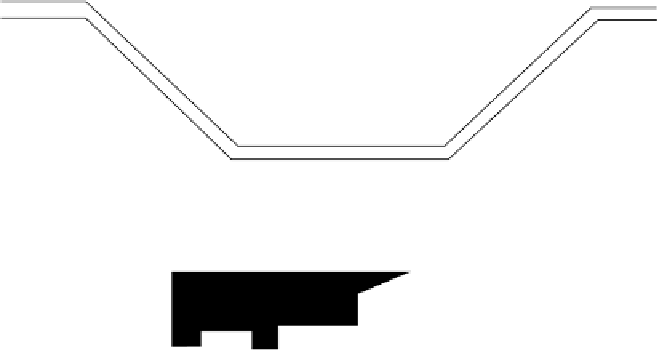

To adsorption device

or atmosphere

Drying

tunnel

Part travel

Hood

Monorail

Degreased

part

Spray

nozzles

Condensing

coil

Free

board

Vapor level

Water jacket

Liquid

level

Condensate

trough

Solvent spray

pump

Boiling sump

Solvent spray

reservoir

Heat source

FIGURE 1.2

Coni guration of typical offset vapor degreaser. (Adapted from University of Tennessee Center

for Industrial Services, 1995.)

The cleaning action of a vapor degreasing system is dependent on the temperature differential

between the vapor and the work. The efi ciency of the process decreases as the work becomes

warmer. Some degreaser operations use cool liquid solvent to presoak the work before bringing it

into contact with solvent vapor; thereby extending the cleaning time, and promoting good solvent

penetration from vapor condensation on the work (Petering and Aitchison, 1945). Some degreas-

ing operations use multiple dips, where the work is moved from a dirty tank to subsequently

cleaner tanks, followed by a i nal cleaning in clean solvent vapor (Dow Chemical Company,

1999b). The higher boiling point of perchloroethylene prolongs the condensation effect in a con-

tinuous degreaser because it takes more time to bring the cold work to perchloroethylene's higher

vapor temperature. Compared to the solvents that have lower boiling points, perchloroethylene is

therefore considered to have better cleaning power per unit of time that the work spends in a con-

tinuous vapor degreaser (Johnson, 1973).

Some degreaser systems are equipped with a wand that can be used to spray warm solvent onto

the work to complete the cleaning process. The physical action of the spray pressure knocks off

the strongly bound soils (AFCEE, 1999; Pro-ACT, 1999; Dow Chemical Company, 1999b).

However, high-pressure sprays can disrupt the vapor blanket, leading to solvent vapor losses,

unless care is taken to spray the work beneath the vapor blanket or inside an enclosed compart-

ment of a vapor degreaser. A diagram portraying the features of a typical vapor degreaser is

shown in Figure 1.2.

Solvent vapors usually remain below the level of the condensing coils; nevertheless, open-top

degreasers routinely incurred substantial solvent losses. Solvent vapors diffuse from the dense

solvent vapor blanket into the overhead air mass at a rate dependent on solvent vapor density and

boiling point and the temperature differential with the ambient air. Tests have shown that vapor loss

Search WWH ::

Custom Search