Environmental Engineering Reference

In-Depth Information

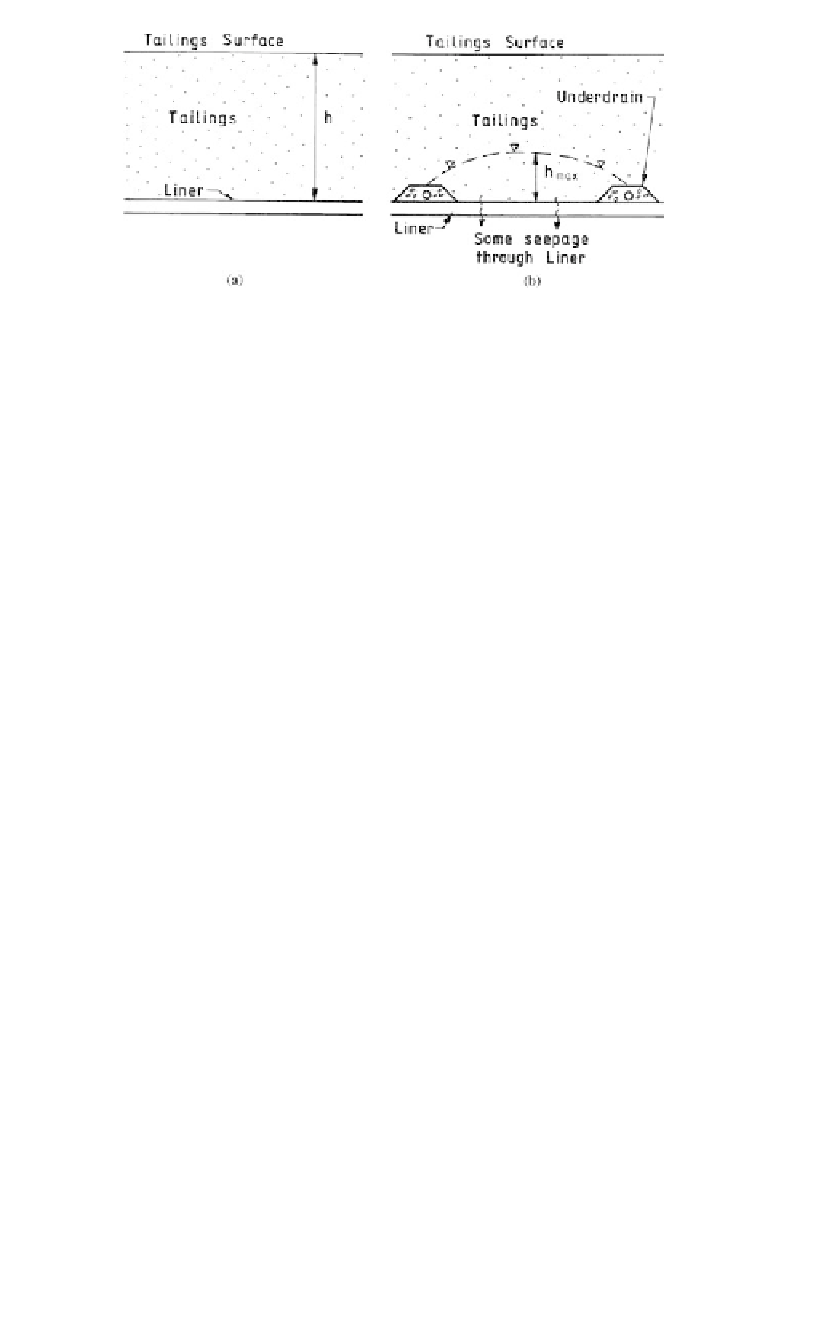

Figure 19.42.

Comparison of head acting on clay liner, (a) without underdrain; (b) with underdrain.

As shown in Figure 19.42 the underdrains may reduce the head on the liner and reduce

the seepage. However, the amount of seepage collected and bypassing the collector drains

is dependent on many factors, as follows:

- The spacing of the drains;

- The vertical and horizontal permeability of the tailings;

- The permeability of the liner. Note that there is a nett head on the liner between the

drains and, even within the drain, water flowing on the liner will percolate through the

liner. If the groundwater level is below the liner, the hydraulic gradient through the liner

will still be at least 1, giving significant seepage;

- The efficiency of removal of water from the drain system.

If no liner has been provided, and the underdrains are laid on the natural ground, there

will still be significant seepage into the ground because while the drain has a permeability

of say 10

5

m/sec the ground will have a significant permeability, e.g. 10

6

m/sec to

10

7

m/sec (if normal weathered rock).

Apart from these design problems, there are some practical aspects:

- The underdrains must be designed to act as filters (as detailed in Chapter 9) to the tail-

ings, or they will rapidly become blocked. Tailings are particularly erodible and will

readily clog a poorly designed filter;

- Geotextiles have been used to construct the drains. However, as outlined in

Scheurenberg (1982) and Bentel et al. (1982), the geotextile should not be exposed

directly to the tailings or it will clog. They overcame this problem by covering the geo-

textile with a layer of filter sand. There is however a chance that the geotextile will still

clog with deposited oxides from the seepage water and their use is not recommended;

- The underdrains are susceptible to contamination by dry windblown tailings, before

they are covered with tailings;

- The seepage water collected in the drains has to be collected and pumped to storage for

use in the process plant. This involves expensive collection and pump systems which have

to be maintained;

- The filters and outlet pipes can be clogged by oxidation products from the tailings.

Figure

19.43

shows an outlet system used by Lyell and Prakke (1988) to overcome this problem.

19.6.4.6

Synthetic liners

Synthetic liners are used to line many hazardous waste facilities, often with the provision

of drainage layers beneath the first membrane, with a second membrane or clay liner to