Environmental Engineering Reference

In-Depth Information

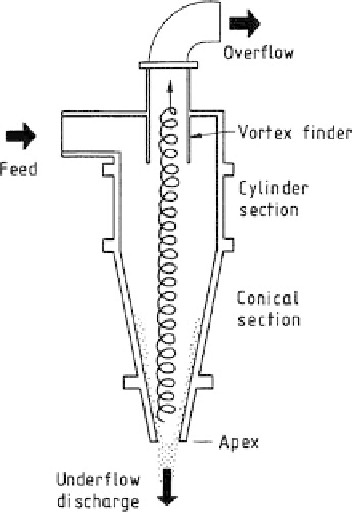

Figure 19.8.

Typical cyclone for tailings.

The use of cyclones is discussed in Vick (1983). He indicates that reasonably clean sand

can be obtained from tailings with less than 60% passing 0.075 mm, provided the tailings

are essentially non plastic and free of clay minerals. Such sands will have high permeability

and high shear strength.

Cycloning may be used in several ways:

-

Stationary cyclone plant

- a central high capacity cyclone station is established near the

dam. Sands from the cyclone can be placed in the dam by conventional earthmoving

equipment, and may be compacted. This may facilitate use of tailings for dam con-

struction in seismic areas;

-

On dam cycloning

- the most common technique. Several small cyclones are set up on

the dam and the underflow discharged on to the embankment. The cyclones are moved

as the dam is raised. Vick (1983) indicates that relative densities of 45% to 55% are

likely to be achieved if no compaction is carried out.

At the El Cobre Tailings Dam in Chile, a large stationary cyclone plant was used, with

the water content of the under flow engineered to give the required downstream slope of

4H:1V. This slope was continuously tracked by a small bulldozer to compact the tailings

to a relative density of at least 65% (Cohen and Moenne, 1991). This material was not

saturated, dense and non liquefiable.

19.3.3

Subaqueous vs subaerial deposition

If for climatic reasons, lack of a large discharge area, acid generation control or other rea-

sons, tailings are deposited under water, the method is known as subaqueous deposition.

Fine, high clay content tailings deposited subaqueously will usually achieve a low settled

density, very low shear strength and will be very compressible. Thus large, costly storages