Environmental Engineering Reference

In-Depth Information

Table 18.7.

Grouting limits of common mixes (Littlejohn, 1985).

Silty or clayey

Type of soils

Coarse sands and gravels

Medium to fine sands

sands, silts

Soil characteristics

Grain diameter

D

10

0.5 mm

0.02

D

10

0.5 mm

D

10

0.02 mm

100 cm

1

100 cm

1

1000 cm

1

1000 cm

1

Specific surface

S

S

S

10

3

m/s

10

3

10

5

m/s

10

5

m/s

Permeability

K

K

K

Type of mix

Bingham suspensions

Colloid solutions (gels)

Pure solutions

(resins)

10

2

m/s)

Consolidation

Cement (K

Hard silica gels double shot

Aminoplastic,

10

4

m/s) Single

grouting

aerated mix

Joosten (for K

phenoplastic

shot: Carongel, Givanol, Siroc

Impermeability

Aerated mix, bentonite gel,

Bentonite gel, lignochromate,

grouting

clay gel, clay/cement

light Carongel, soft silicagel,

vulcanisable oils, others

(Terranier)

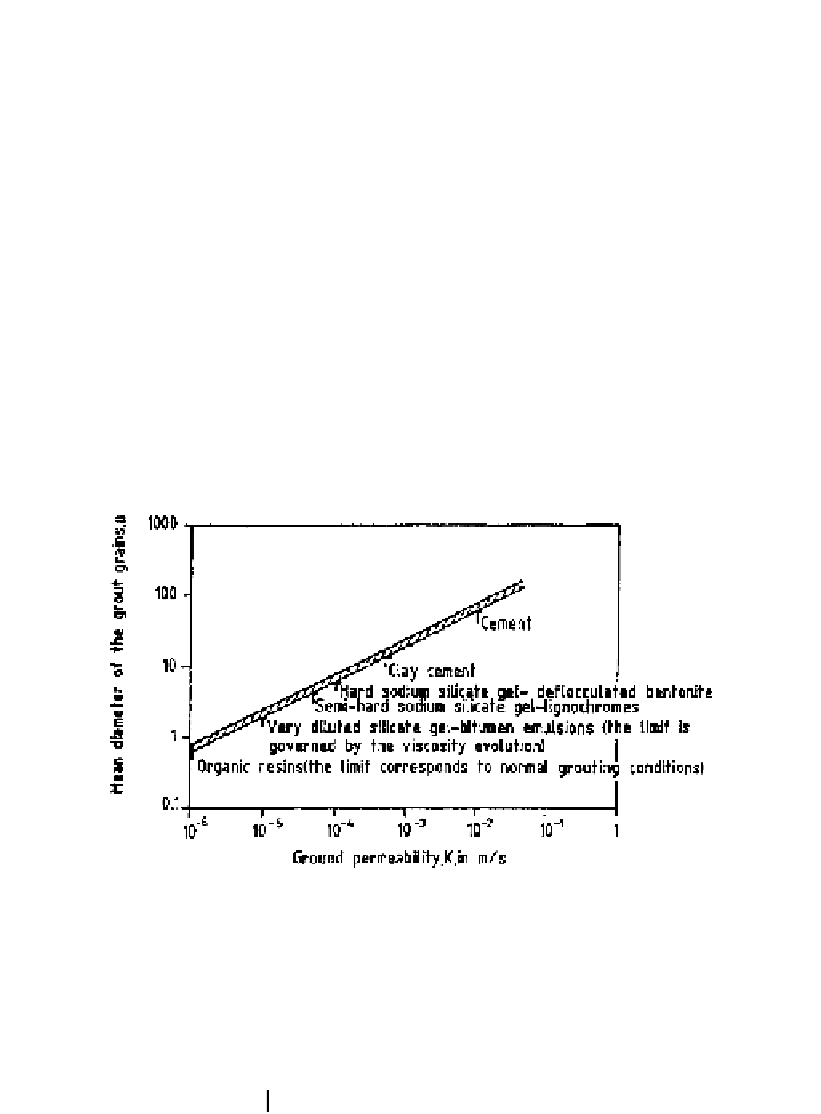

Figure 18.26.

Limits of injectability of grouts based on the permeability of sands and gravels

(Littlejohn, 1985).

where Q

flow rate at radius of penetration R and the time for grout to penetrate.

nr

kH

2

R

r

3

3

1

R

r

2

2

t

1

1

(18.7)

3

2

i.e. time is proportional to R

3

. This dictates that relatively close hole spacings are used for

economic grout times, e.g. 0.5 m to 2.5 m.

There are different tables and graphs indicating the types of soils and soil permeability that

can economically be grouted, e.g. Littlejohn (1985) suggests Table 18.7 and Figure 18.26.

Karol (1985) suggests that, based on a review of the literature,

Figure 18.27

is a con-

servative assessment of groutability by permeation, i.e. without fracturing.