Environmental Engineering Reference

In-Depth Information

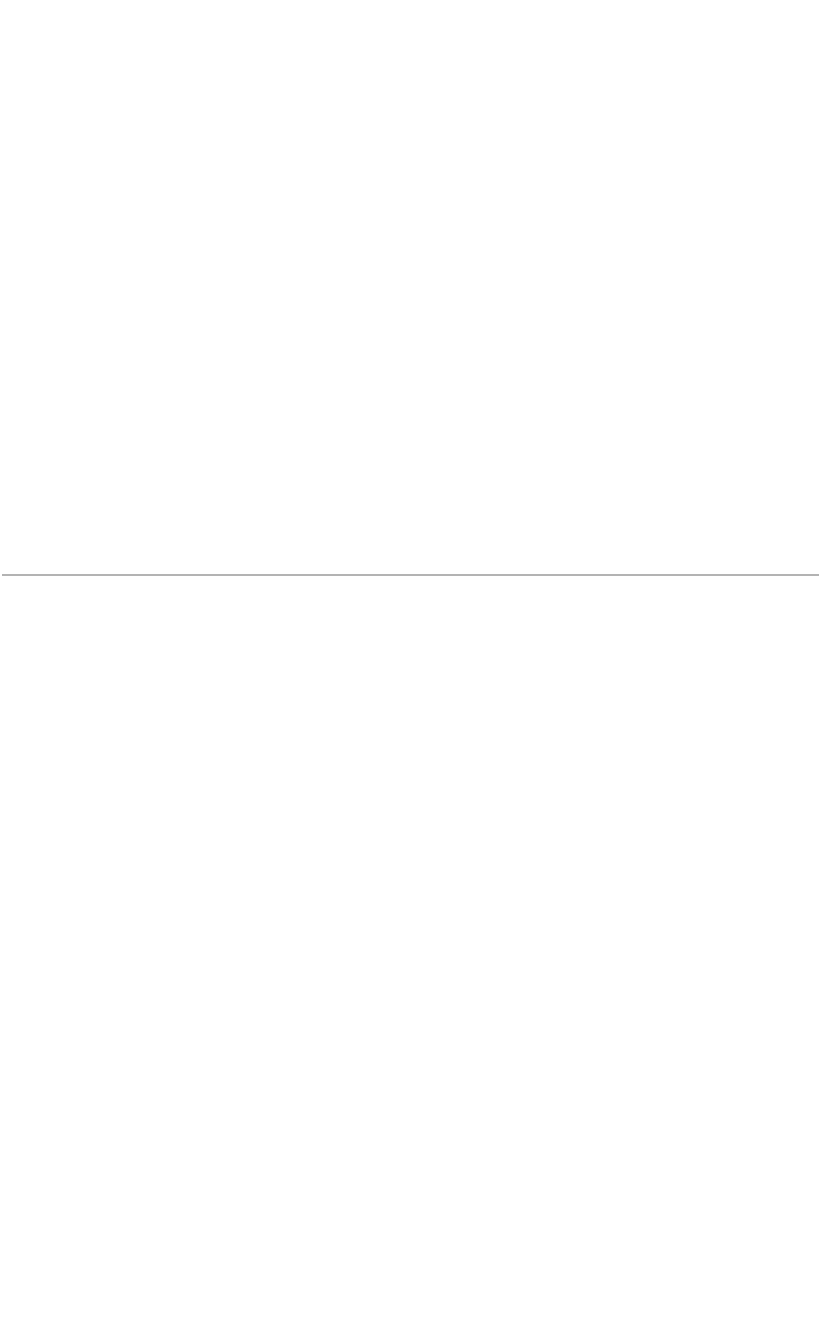

Table 14.3.

Practical maximum layer thickness (m) after compaction for different types of rollers at dif-

ferent applications (Forssblad, 1981).

Embankment

Roller type static weight (drum

module weights in brackets)

Rockfill (1)

Sand gravel

Silt

Clay

Sub base

Base

Towed vibr. rollers

6tonnes

0.75

*0.60

*0.45

0.25

*0.40

*0.30

10 tonnes

*1.50

*1.00

*0.70

*0.35

*0.60

*0.40

15 tonnes

*2.00

*1.50

*1.00

*0.50

*0.80

-

6 tonnes padfoot

-

0.60

*0.45

*0.30

0.40

-

10 tonnes padfoot

-

1.00

*0.70

*0.40

*0.60

-

Self-propelled vibr. rollers

7(3) tonnes

-

*0.40

*0.30

0.15

*0.30

*0.25

10(5) tonnes

*1.50

*1.00

*0.70

*0.50

*0.40

8(4) tonnes padfoot

-

0.40

*0.30

*0.20

0.30

-

11(7) tonnes padfoot

-

0.60

*0.40

*0.30

0.40

-

15(10) tonne padfoot

-

1.00

*0.70

*0.40

0.60

-

Vibr. tandem rollers

2tonnes

-

0.30

0.20

0.10

0.20

*0.15

7tonnes

-

*0.40

0.30

0.15

*0.30

*0.25

10 tonnes

-

*0.50

*0.35

0.20

*0.40

*0.30

13 tonnes

-

*0.60

*0.45

0.25

*0.45

*0.35

18 tonnes padfoot

-

0.90

*0.70

*0.40

0.60

-

Notes: (1) For rock fill only rollers especially designed for this purpose.

(2) Most suitable applications marked*.

It has been common practice in Australian dam engineering (and elsewhere) to

specify a layer thickness of 150 mm after compaction. USBR (1991) suggest

150-200 mm loose thickness for rolling with sheepsfoot rollers, and 225-300 mm

loose thickness for rolling with 50 tonnes rubber typed rollers.

The 150 mm layer thickness after compaction is probably unnecessarily thin for mod-

ern heavy rolling equipment. Table 14.3 from Forssblad (1981) shows for different soil

types the practical maximum layer thicknesses for a range of roller types and weights

indicating that 6 tonnes to 10 tonnes pad foot rollers can compact layers up to 0.3 m and

0.4 m thick respectively. While these figures may represent an upper practical limit, they

do show that a 150 mm layer is unnecessarily restrictive. It could be argued that, as a

performance specification has been adopted for earthfill, i.e. water content and density

ratio, there is no need for the “method or procedure specification” limitation on layer

thickness. The authors' own preference is to specify layer thickness but to use more real-

istic figures, e.g. 200 mm or 250 mm for a 11 tonnes self propelled pad foot roller.

(e)

Placement and spreading

Earthfill may be placed by scrapers or dumping from a truck and spreading with a

grader or bulldozer. Oversize material should be removed before compaction.

The surface of the previously compacted layer should be scarified prior to placing

the next layer of fill to ensure good bond. It may be necessary to add a small amount

of water to the scarified surface prior to placing the fill. Care should be taken to

ensure a uniform material. Segregation is likely to be a problem if gravel sized parti-

cles are allowed in the earthfill.

(f)

Roller type, weight, and number of passes

It is normal to specify the roller type and weight. For earthfill it is most common to

require a tamping foot (or “sheep's foot” or “pad foot”) type roller because:

- The tamping foot action breaks up pieces of cemented soil or weathered rock in the fill;