Environmental Engineering Reference

In-Depth Information

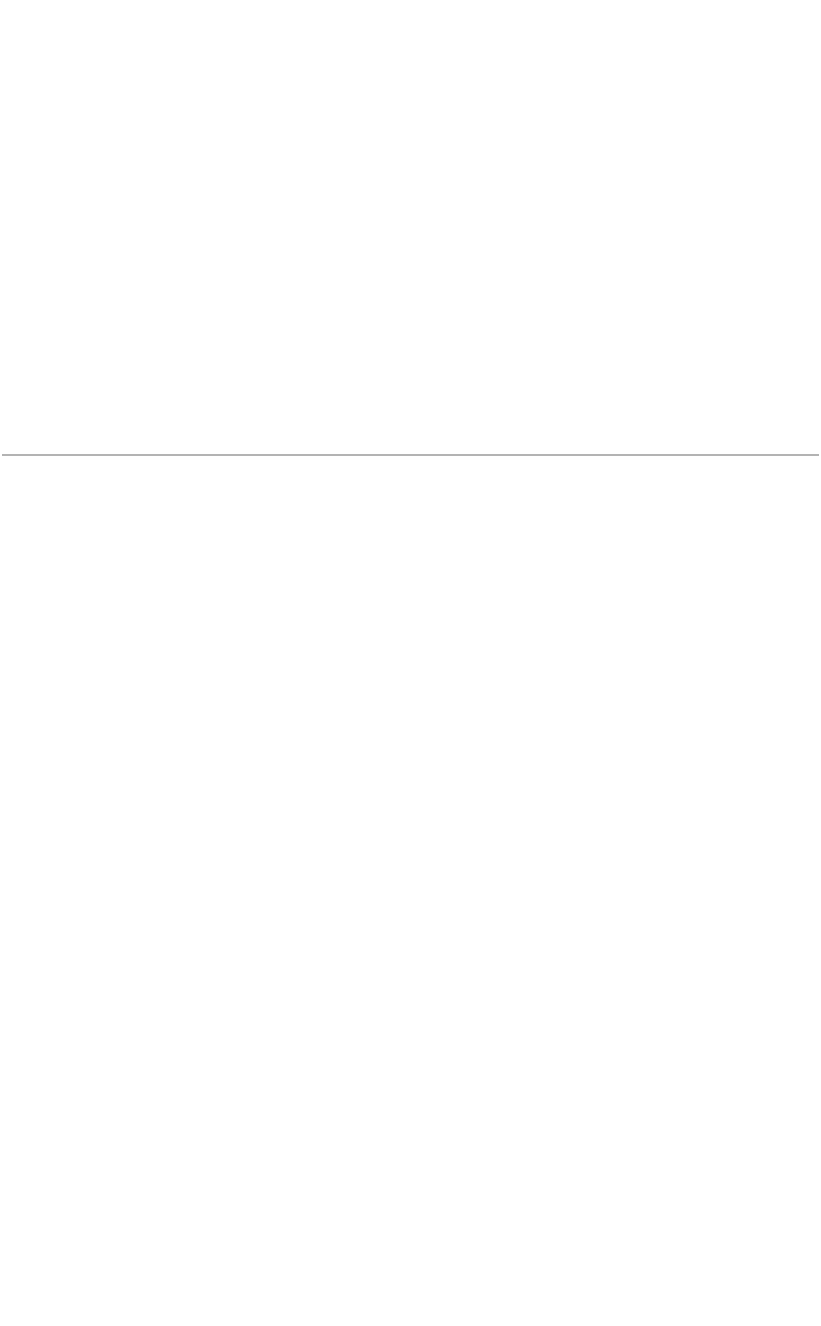

Table 14.2.

Examples of rockfill grading requirements.

Grading requirement

Layer

Size largest

Dam

Dam type

Zone

thickness (m)

particle (mm)

% Other grading limits

Cardinia Creek E & R

3A

1.8

300

20% passing 25 mm

Harding

E & R

3A

1.0

150

30% passing 20 mm and

10% passing 1.18 mm

Harris

E & R

3A

1.0

150

30% passing 20 mm and

10% passing 1.18 mm

Thomson

E & R

3A

1.0

150

30% passing 19 mm and

10% passing 1.18 mm

Winneke

CFRF

3A

0.7

Not specified

10% passing 0.075 mm

3B random

0.4

Not specified

20% passing 0.075 mm

Boondooma

CFRF

3A

0.6

75

15% passing 1.18 mm and

5% passing 0.075 mm

3B

0.9

75

15% passing 1.18 mm and

5% passing 0.075 mm

and to the depth of the layer would have to be dug to obtain a representative sample.

Several tonnes of rockfill would be involved.

- The upper part of each layer is likely to be finer than the lower part, because of

segregation in placing and breakdown of rockfill under the rolling action. For

vertical seepage the permeability of this broken material will dominate. If, however,

it is a normal situation where horizontal drainage is most important, such

breakdown may not be important, provided the lower part of the layer remains

permeable.

In any case the breakdown is a fact of life and the design must accommodate it. Table

14.2 gives some examples of rockfill grading requirements. These are for quite large

dams for which it may have been practical to specify the grading to the extent done and

to demonstrate that it was achievable by trial quarrying and fills. For most projects, for

free draining high permeability rockfill, the authors favour an approach which requires

that for the rockfill after compaction:

(a) The maximum particle size to be the compacted layer thickness;

(b)

10% or 15% passing 1.18 mm;

(c)

5% passing 0.075 mm, and

(d) Water not to pond on the surface of the compacted layer.

The grading would be checked by inspection and only measured if it became necessary

from a contractual viewpoint to confirm the percentage of finer particles was

excessive.

A guide to excessive fines can be if the fill moves excessively as it is being rolled, or

trucks bog on the fill. This also indicates the fill does not have a high permeability.

(d)

Placement and spreading

Usually the rockfill is dumped from trucks on the surface and spread by a bulldozer. In

so doing the fines are moved onto the upper part of the layer, which creates a smoother

working surface for the truck to place the next layer and the stratified permeability dis-

cussed above. Oversize rocks are often pushed into a specified zone (e.g. Zone 3B) in

the outer part of the dam. To meet the filter requirements is important to ensure that

the contact between Zones 2B and 3A does not have an accumulation of large rocks.