Environmental Engineering Reference

In-Depth Information

Millet et al. (1992) emphasise the need to hydrate the bentonite before mixing in

cement and aggregates.

The concrete (either conventional or plastic) must be placed in the wall by a tremie pipe

to avoid segregation. Xanthakos (1979) indicates that it is desirable to complete the con-

crete pours in less than 4 hours to avoid any significant stiffening of the concrete. For pan-

els up to 3.5-4.5 m long, a single tremie pipe is adequate but, for longer panels, two pipes

may be needed.

Reinforced concrete guide walls are constructed ahead of the trenching operation, for

diaphragm walls filled with grout or concrete. The guide walls:

- Control the line and grade in the trench;

- Support the sides of the trench from heavy construction loads;

-Protect the sides of the trench from turbulence and erosion;

- Can be braced to support the top of the trench;

- Act as a guide trench for the slurry.

Xanthakos (1979) gives details of guide wall design.

10.4.6

Methods of excavation of diaphragm walls

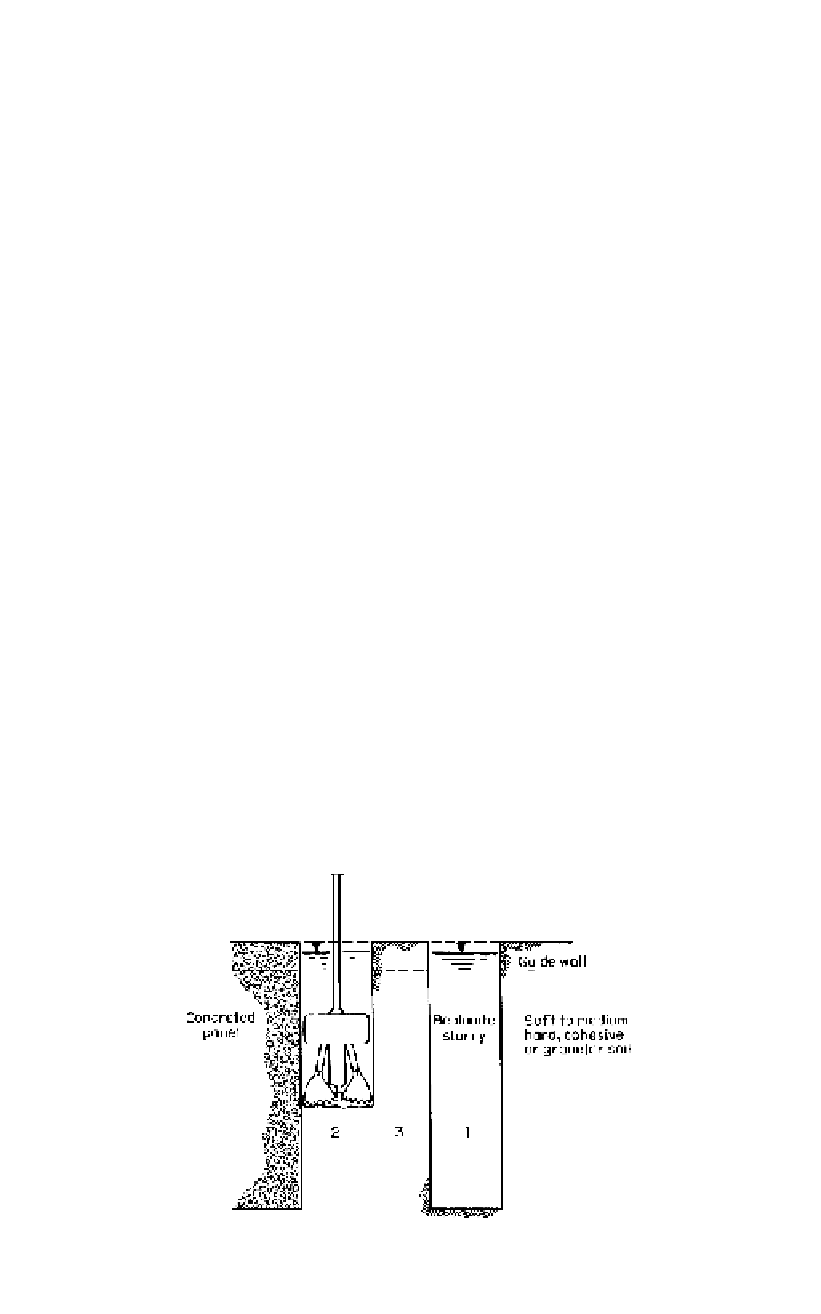

Diaphragm walls are usually excavated as a series of panels, each panel as a series of

passes as shown in Figure 10.24.

This method can be applied to soft to medium hard, granular and cohesive soils, provided

there are not boulders or other obstructions. The minimum “pass” is about 2 metres, the

maximum about 6 m.

Excavation will usually be carried out using clamshell type bucket as shown in Figure

10.24. The clamshells are of two types:

(a) Cable suspended which:

-Are easy to keep vertical;

-Are manouverable;

- Can work in limited headroom;

Figure 10.24.

Single stage panel excavation with clamshell bucket: Passes 1 and 2 spread of clamshell

bucket; Pass 3 spread of clamshell bucket minus clearance for grab to embrace soil

(Xanthakos, 1979, reproduced with permission of McGraw-Hill).