Environmental Engineering Reference

In-Depth Information

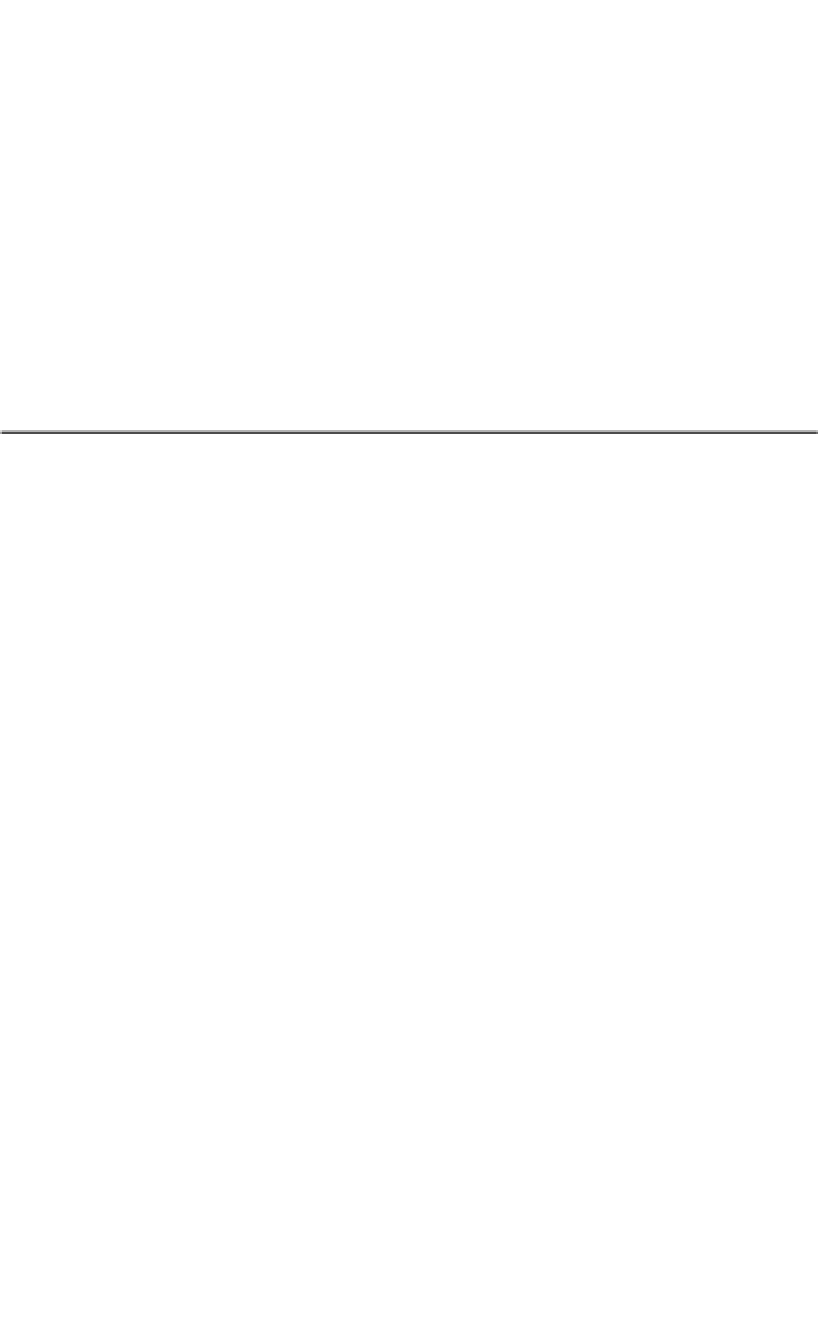

Table 9.14.

Clogging criteria (Christopher, et al., 1994).

A

Critical/severe applications

Perform soil/geotextile filtration tests (e.g. Calhoun, 1972; Haliburton, et al., 1982a and b;

Giroud, 1982; Carroll, 1983; Christopher and Holtz, 1985 and 1989; Koerner, 1990).

B

Less critical/non-severe applications

1. Perform soil/geotextile filtration tests;

2. Minimum pore sizes alternatives for soils containing fines, especially in a non-continuous

matrix:

a. O

95

3D

15B

for C

u

3 (Christopher and Holtz, 1985 and modified 1989);

b. O

f

4D

15B

(French Committee on Geotextiles and Geomembranes, 1986);

c. O

15

/D

15B

0.8 to 1.2;

O

50

/D

50B

0.2 to 1 (Fischer, et al., 1992).

3. For C

u

3, geotextile with maximum opening size from retention criteria should be specified;

4. Apparent open area qualifiers;

Woven geotextiles: present open area

4% to 6% (Calhoun, 1972; Koerner, 1990);

Nonwoven geotextiles: porosity

30% to 40% (Christopher and Holtz, 1985; Koerner,

1990).

(b) Durability during operation, both from a viewpoint of mechanical issues, e.g. ability

to cope with differential deformations, and chemical durability.

Heerten (1993) suggests using a geotextile with a mass of not less than 300 grams/m

2

.

This was based on tests where sites were exhumed after construction;

Christopher et al. (1993) suggest trialling the geotextile in the application proposed and

exhuming trial sections to show the geotextile is sufficiently robust;

Giroud and Bonaparte (1993) give some advice on construction practice:

-

If the soil is placed or excavated before geotextile placement, its surface should be as

smooth as possible. This requirement is particularly important if the geotextile filter is

part of a stiff geocomposite. If the soil is placed after the geotextile, it should be com-

pacted to eliminate voids in the vicinity of the geotextile;

-

The geotextile should be installed to be not too taut, but also not too loose (wrinkles must

be avoided). If the geotextile is placed on a previously placed or excavated soil, all efforts

should be made to follow the shape of the soil. If proper contact cannot be ensured,

because the geotextile is part of a stiff geocomposite, sand should be placed between the

soil and the geotextile. The sand particle size must be compatible with the soil particle size

and the geotextile opening size;

-

The aggregate, if any, used in contact with the geotextile must be small enough to

apply a uniform stress on the geotextile in order to properly confine the soil located

on the other side of the geotextile. A maximum aggregate size of 20 mm is recom-

mended.

The long term chemical durability of geotextiles has been and remains a significant con-

cern. Giroud and Bonaparte (1993) indicate examples of successful operation for up to 35

years. However concerns on long term durability remain e.g. ICOLD (1986) (and by impli-

cation ICOLD, 1994).

9.7.2.5

Use of geotextile filters in dams

Use of geotextiles to perform a permanent function, probably in lieu of a sand/gravel fil-

ter, does require consideration of the effectiveness of the geotextile as a “filter” and

“drain” as has been discussed in preceding Sections. It also requires consideration of long-

term function without damage due to deformation or clogging and durability, particularly