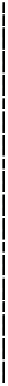

Environmental Engineering Reference

In-Depth Information

AUSTRALIAN

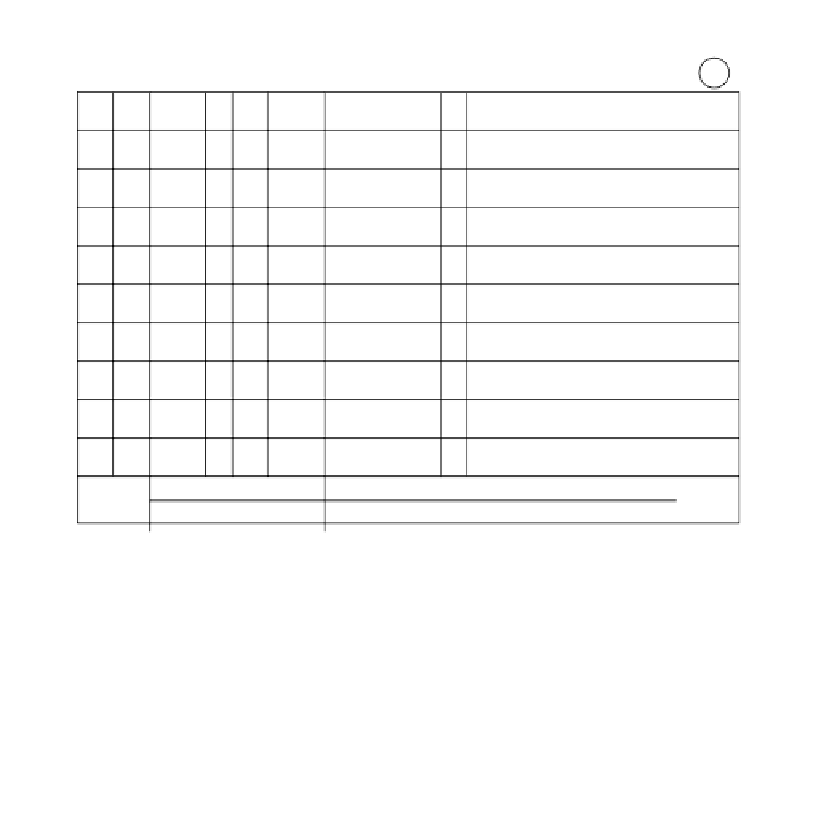

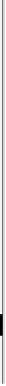

STANDARD SIEVES

8A

100

0

10

90

8B

D85B

20

80

70

30

7B

60

40

50

50

2A

2B

40

60

30

70

6C

20

80

7A

6A

5

10

90

6B

0

100

CLAY

S I L T

S A N D

G R A V E L

Cobbles

Fine

Medium

Coarse

Fine

Medium

Coarse

Fine

Medium

Coarse

0.002

0.006

0.01

0.02

0.06

0.1

0.2

0.6

2

6

20

60

200

0.001

1

10

100

PARTICLE SIZE (mm)

Notes:

Step 1 - Particle size distribution for Zone 2A becomes the “Base Soil” - the fine side boundary is

critical. D

85B

15% passing 0.075 mm). Step 5 -

(5). Step 6 - Determine permeability criterion, D

15Fmin

2.5 mm. Go to Step 4. Step 4 - Soil is type 3 (

2% passing 0.075 mm

(6B), D

15Fmin

4D

15B

4 x 0.7 mm or

2.8 mm. However for average D

15

= 4

0.3 mm

1.2 mm accept this (6C). Step 7 - D

XFmax

/D

XFmin

less than 5 e.g. D

15Fmax

= 10 mm, therefore

D

15Fmin

2 mm (7A), D

60

/D

10

less than 6, so say D

10Fmax

6.7 mm, D

60Fmax

40 mm (7B);

Follow step 7 at 60% Passing when finalising grading. Step 8 - D

10F

0.1 mm, (6A),

7 mm, so max D

90F

50

mm from

Table 9.7

(8B).

Figure 9.27.

Example of design of a Zone 2B filter.

9.5.2.1

Standard tests for durability

Table 9.10

shows the specified durability requirements for several dams constructed in

Australia. Also shown for comparative purposes are the requirements for fine and coarse

concrete aggregates as specified by Standards Association of Australia (1985).

These specifications can be used as a guide to selecting reasonable limits. The following

comments are offered:

(a) The Los Angeles abrasion and wet strength, wet/dry strength variation tests largely

assess the susceptibility to breakdown under the mechanical action of placement and

rolling in the dam. It can be seen that dam specifications are generally less stringent

than AS2758.1. If materials test marginally within the specification it would be advis-

able to carry out field compaction trials of the filters, to observe directly the degree of

breakdown under rolling and the size of the “broken down” product. It may be prac-

ticable to make design changes, e.g. wider or thicker filters, to accommodate the

breakdown.

(b) The Sodium Sulphate soundness test assesses the susceptibility to breakdown under

wetting and drying, with the added involvement of sodium sulphate in the solution