Environmental Engineering Reference

In-Depth Information

determine the continuing erosion boundary for soils with D

85B

0.1 mm. The test proce-

dures of the CEF tests were essentially the same as those of the NEF test, as described by

Sherard and Dunnigan (1989), but with the following modifications:

-Water passing through the filter during the tests was collected and the eroded materials

dried and weighed to determine the loss of base soil required to seal the filter;

-Progressively coarser filters were used until the filter was not sealed;

- Thicker base specimens were used to allow for greater erosion losses.

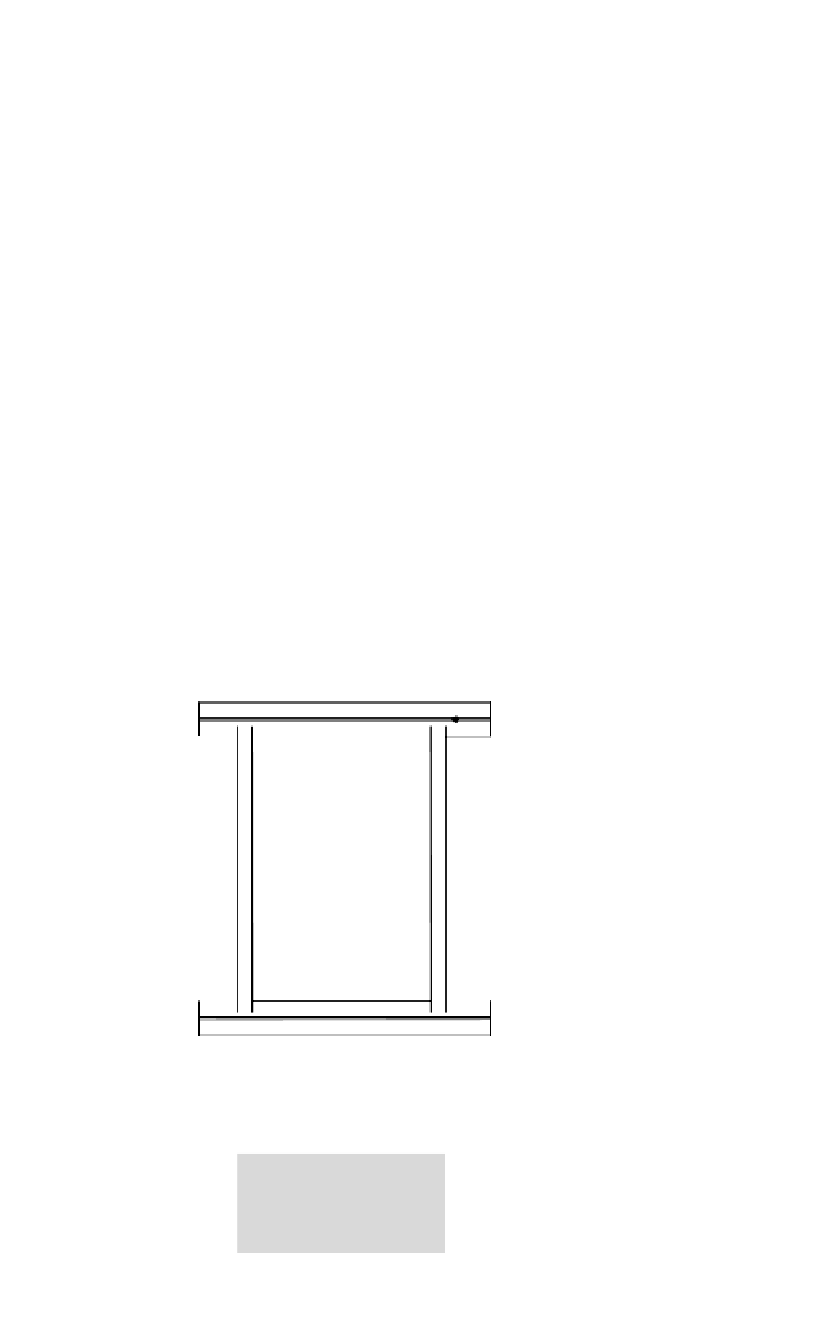

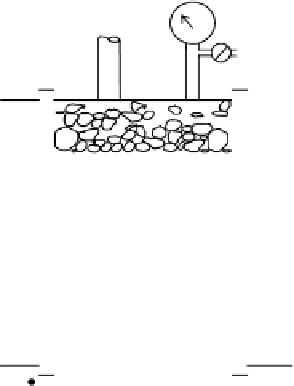

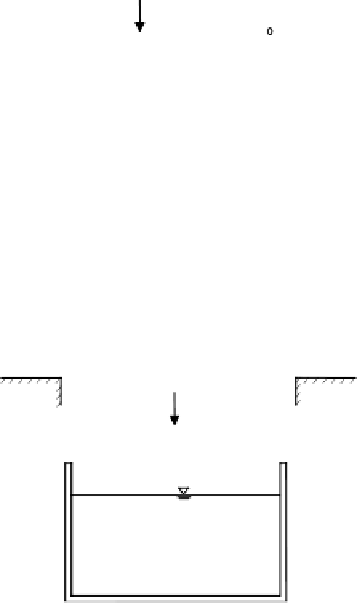

Details of the CEF test setup are shown in Figure 9.21.

The tests were carried out for until it was evident the filter was sealed or it was

judged that the filter was not going to seal no matter how much erosion of the base soil

occurred. The filters were judged to have sealed when all of the following conditions were

reached:

- Full mains pressure was maintained in the space above the base specimen as measured

on the pressure gauge;

-Water passing through the filter was clear;

- The flow rate of water passing through the filter had decreased substantially from the

initial flow and was relatively constant.

From mains

water supply

(240-300kPa)

From mains

Pressure gauge

19 mm dia. inlet pipe

Air vent

Top gravel layer

Preformed hole in base specimen

(1.0 to 2.0 mm dia. for NEF tests

and 5mm for dia. for CEF tests)

125 mm dia.

clinder for

DF15

15 mm

Compacted base specimen

(25 mm thick for NEF tests and

100mm thick for CEF tests)

205 mm dia.

cylinder for

DF15

15 mm

Side material

Filter material

(150 mm thick for DF15

15 mm

200 mm thick for DF15

15 mm)

Bottom drainage layer

Two 19 mm dia. outlet pipes

0.075 mm sieve

Eroded core materials

Plastic drum (s)

Figure 9.21.

Continuing erosion filter test apparatus (Foster and Fell, 1999a, 2001).