Environmental Engineering Reference

In-Depth Information

F

C

10

2

y

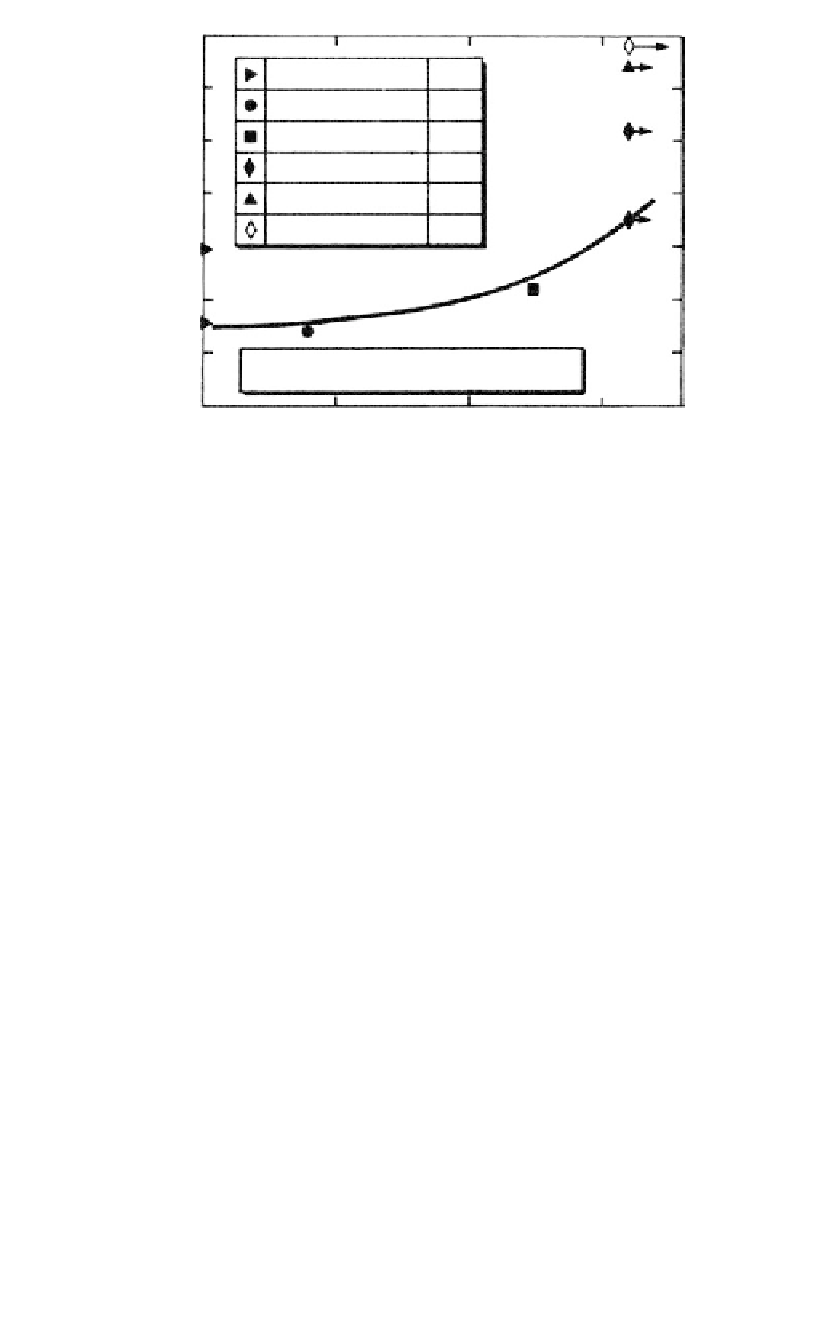

W.E.S. LAB TESTS

80

OGISHIMI FILL

KAWAGISHI-CHO

FILL

1y

(N

1

)60

D

R

C

30y

100y

100y

100y

NIIGATA SAND

NIIGATA SAND

SIZEWELL SAND

∗

(

∗

) OVERCONSOLIDATED

60

F

C

F

40

F

AVER

F

F

FINE SAND

D

50

0.4 mm

C

COARSE SAND

D

50

0.4 mm

20

10

1

1

10

AGE OF DEPOSIT (YEARS)

100

Figure 6.34. Effect of aging of the soil on SPT resistance (Jamiolkowski et al., 1988).

Robertson and Campanella (1984) and two other methods were to be preferred. The

Robertson and Campanella (1984) method is simple to use and is shown in

Figure 6.35

.

They indicate that:

-

The method applies to normally consolidated, uncemented, moderately incompressible

(grains), predominantly quartz sands but can be used for silty sand, sandy silt, sand and

gravelly sand;

-

For highly over-consolidated sands

may be up to 2° lower than predicted from

Figure 6.35;

-

For highly compressible sand (e.g. sand with many shells, or mica pieces) the method

predicts conservately low friction angles. For the sands included in Robertson and

Campanella's analysis the effect could be up to 3°.

The in-situ methods described give peak strength (not large strain, steady state strength)

and do not appear to account for any curvature of the strength envelope. Hence if it is

intended to construct a large dam on such a foundation, it may be necessary to account

for this by using somewhat lower strengths. The Jamiolkowski et al. (1985) method

allows for this.

6.1.9.2

Laboratory tests

Laboratory tests to determine the effective friction angle of granular materials are

described in ASTM and British standards and in Head (1985).

The most difficult aspect is to be able to prepare the sample at the correct relative den-

sity. Coarse grained materials (containing gravel) may have to be re-graded so they can be

tested. The normal procedure is to prepare soils with a particle size distribution finer than

and parallel to the actual.

6.1.9.3

Empirical estimation

A good guide to the strength of compacted sand and sandy gravel is to use the relative

density specified (or expected), and particle size and use

Figure 6.33

.