Environmental Engineering Reference

In-Depth Information

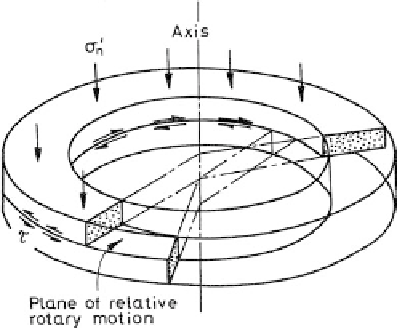

Figure 6.19.

Ring shear test sample.

For the Bishop et al. (1971) machine (manufactured by Wykham Farrance) the sample

is 150 mm outside diameter, 100 mm inside diameter, and 19 mm thickness. Remoulded

samples are usually tested, but undisturbed samples can be placed in the equipment. The

machine is mechanically complex and expensive, putting it largely in the research cate-

gory. Bromhead (1979) and Bromhead and Curtis (1983) describe a simpler ring shear

device. The test procedure is detailed in BS1377-7:1990, and ASTM D6467-99.

Bromhead (1986) and Clayton et al. (1995) give some practical details on how to operate

the equipment. The sample in the Bromhead machine is outside diameter 100 mm, inside

diameter 70 mm and only 5 mm thick.

The ring shear devices have essentially unlimited “strain” availability, so overcoming

the major objection to the reversing direct shear test. However, there are limitations:

-

only remoulded samples can be tested (in the Bromhead machine);

-

only the residual strength can be obtained. The peak strength is affected by remoulding

and non uniform stress conditions;

-

the sample may tend to squeeze out the sides of the ring. The Bishop machine is con-

structed to overcome this and can be used for softer clays than the Bromhead machine;

-

saturation and testing at a strain rate appropriate to give the required drained condi-

tions is necessary as for the direct shear test.

6.1.4.4

Comparison of field residual with laboratory residual strength obtained from

direct shear and ring shear

There have been a number of papers published comparing field residual strengths

obtained by back-analysis of landslides, and laboratory direct shear testing of the undis-

turbed slide plane, with residual strengths obtained from multiple reversal direct shear,

and ring shear tests. These include Bishop et al. (1971), Townsend and Gilbert (1973),

Bromhead (1979) and Bromhead and Curtis (1983) and Skempton (1985).

In summary the literature indicates that:

-

Direct shear tests on the slide plane or bedding plane shear are the most reliable indi-

cator of field residual strength;

-

Ring shear devices either underestimate by 1° to 2° or approximate the field residual;

-

Multiple reversal direct shear on clays will probably overestimate field residual by

1° or 2°;