Environmental Engineering Reference

In-Depth Information

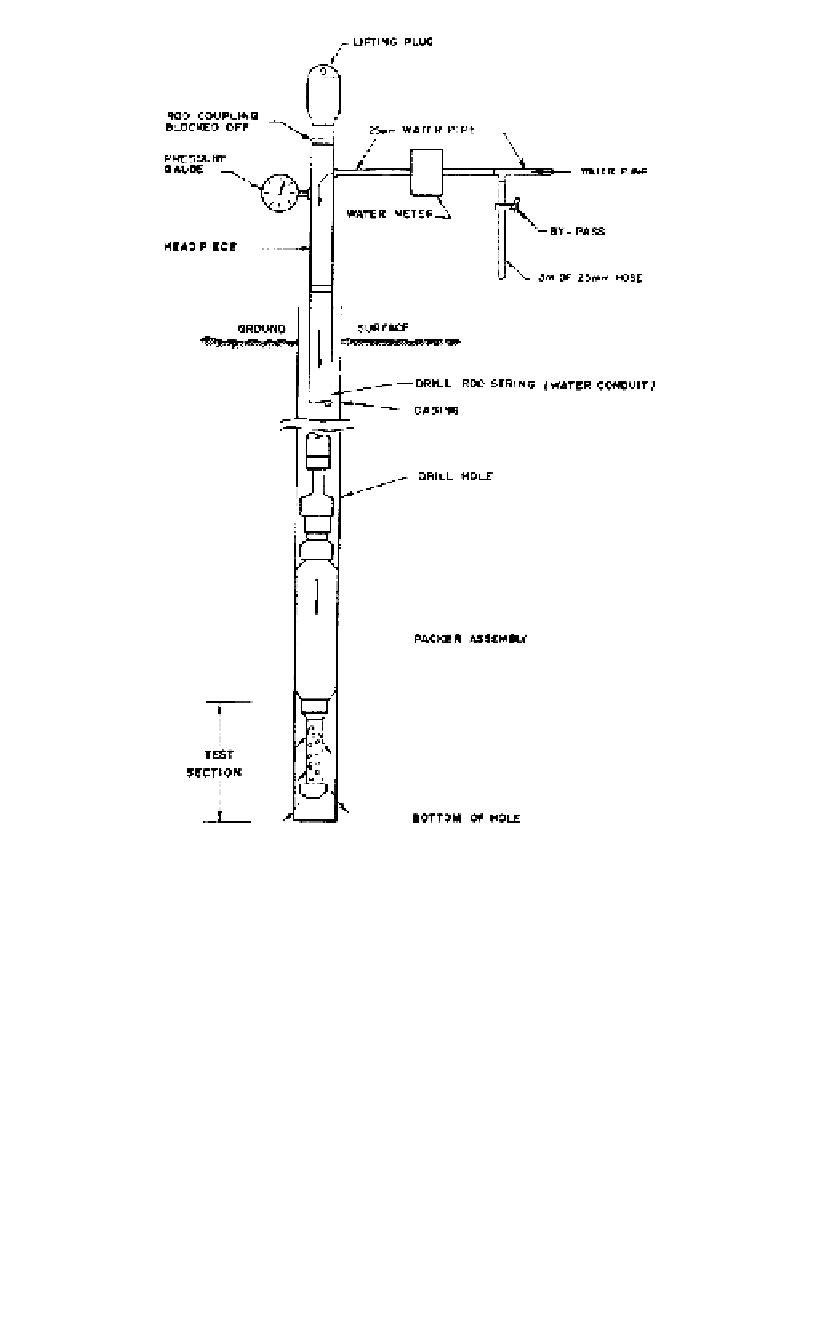

Figure 5.33.

Hydraulic packer equipment (Coffey Geosciences).

Hydraulic packers have proved reliable under most conditions. It is necessary to

ensure that the hole outside the water line is kept full, as outflow from this area indi-

cates possible leakage past the packer, and also it is necessary to equalise the pressures

and allow effective inflation and deflation of the sleeve;

-

In a

pneumatic packer

the sleeve is inflated by air from a compressed air bottle using a

separate air line to the surface. This method is effective in shallow holes, but with deeper

holes fracturing of the air line has caused problems. Water levels do not affect inflation

or deflation;

-

Wireline packers

have been developed for testing holes drilled with wireline equipment.

These enable water pressure testing without the withdrawal of the drill rods. The packer

incorporates two sealing sleeves, the upper seal within the drill rods and the lower seal in

the hole below the drill bit;

-

The

mechanical packer

seals by the expansion of two or more rubber rings when com-

pressed (

Figure 5.34

)

. The test section length is controlled by the insertion of a selected

length of perforated rod below the packer. Sealing is achieved by downward pressure on

the drill string by the drill chuck. This pressure must be maintained throughout the test.