Environmental Engineering Reference

In-Depth Information

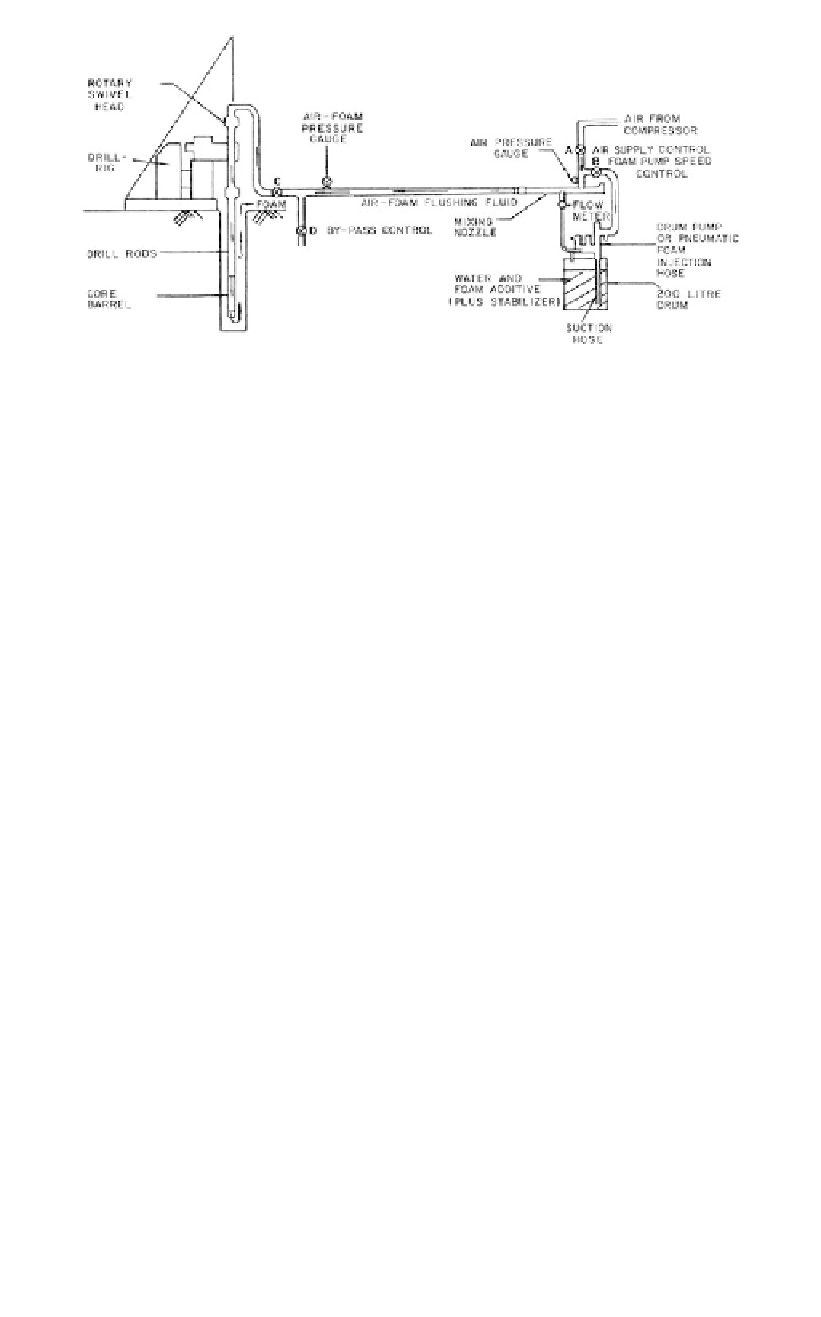

Figure 5.20.

Schematic layout of air-foam and flushing system (Brand and Phillipson, 1984).

Despite the “reverting” nature of the mud, the authors' experience is that perme-

abilities obtained by water pressure testing in holes drilled with mud are lower than

those obtained in holes drilled with water.

Chemical drilling muds can be used to improve recovery when coring in weak, erodi-

ble rock or stiff to hard soils. Core recovery can also be improved by using chemical

foam instead of water or mud. This is described in Brand and Phillipson (1984), and

illustrated by Figure 5.20.

(b)

Core Drilling

, an annulus of rock is removed using a hollow bit with a leading edge

impregnated with fragments of diamond or tungsten carbide, leaving a cylinder, or

core, of rock which can be removed by the core barrel. In conventional core drilling

(

Figure 5.18

)

the barrel is connected to the end of drilling rods which convey the cir-

culating fluid to the bit. Each time the core barrel is filled the rods have to be

removed.

In wireline drilling (

Figure 5.21

) the use of thin-walled rods and a special core barrel

enables the core to be raised inside the rods and significantly reduces the time involved in

drilling deep holes. The core recovered by wireline is slightly smaller in diameter than for

conventional drilling (NMLC core 52 mm, NQ3 core 45 mm).

The objective of site investigation drilling is to obtain the maximum amount of infor-

mation on subsurface conditions. Every effort is required to recover as much core as pos-

sible. In low strength, fractured rock this may involve many short runs with low thrust

and drilling water pressures. Triple tube, stationary inner tube, core barrels reduce core

disturbance, improve core recovery and should be used in dam investigations.

In the analysis of foundation conditions, particularly in relation to slope movement and

potential leakage, the nature of the low strength material is most important. A drilling

programme which recovers all the strong rock and loses all the weak material is ineffec-

tive and its results may be misleading. As a matter of course drillers should be required to

comment on the probable reasons for every section where core has not been recovered.

Drilling contracts should be worded to ensure effective core recovery rather than rapid

drilling progress. The loss of 1 m of core in the upper part of the hole may be much more

important than the recovery of 10 m of fresh core at the base of the hole.

Placement of the core in boxes and logging of the core should emphasise sections where

core was not recovered as these may represent crucial zones in the foundation.

The choice of the core size to be used has to be considered in relation to the ability to

provide full core recovery. Larger diameter core is more expensive to drill, but is likely to

produce a higher core recovery in low strength and fractured rock.