Java Reference

In-Depth Information

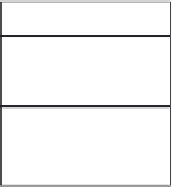

ControllerInterface

Runnable

void openPump(String

name, int percent)

void run()

Pump

Tank inputTank

Tank outputTank

int outFlow

TankController

PumpInterface

void setOutputFlow

(int percent)

int tankLevel

String tankState

TankInterface tank

PumpInterface pumpA

PumpInterface pumpB

void setOutput

Flow()

void flush()

Tank

void setMode()

void openPump(...)

void run()

TankInterface

int getLevel()

double color[]

int capacity

int level

int getLevel()

void push()

void pull()

MixerController

ControllerInterface redController

ControllerInterface greenController

ControllerInterface blueController

void run()

Figure 13.11

The class diagram of Prototype 2

As we have described in the previous section, the PLCs behave like finite

state automata, whose state transitions fire when the paint level of a colour

tank or mixer tank reaches the values of predefined thresholds. This means

that the PLCs should measure the current paint level of the tanks continu-

ously. This approach is consistent with the mechanism used to get state

information from a physical device.

13.5.3

Implementation

The implementation of the second prototype requires the transformation of

the work cell simulator into a remote application in order to allow the PLCs

to exchange data and commands with the simulated devices via the internet.

Since we decided to use Java RMI for the interconnection of remote objects,

we have to define the interfaces exported by the

Tank

and the

Pump

classes,

i.e.

TankInterface

and

PumpInterface

. These interfaces indicate which

methods can be invoked by a remote application. Then, we modify the

declaration of class

Tank

and class

Pump

so as to extend the basic class

UnicastRemoteObject

. Their constructors should declare that they throw

java.rmi.RemoteException

. Finally, class

Simulator

registers the device objects

with unique names using the

java.rmi.Naming

class.