Java Reference

In-Depth Information

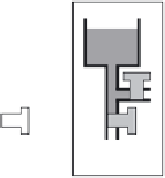

TankInterface

PumpInterface

int getLevel()

void setOutputFlow(int percent)

Figure 13.4

The interfaces of two physical devices

has a well-defined communication interface. Similarly, we simulate the

behaviour of the physical devices by implementing objects that export well-

defined interfaces. Basically, a PLC needs to access the value of the current

level of paint in a tank and to set the output flow of a pump. Figure 13.4

shows the UML definition of the tank and pump interfaces.

The equipment of the car painting work cell is physically distributed over

a wide area. Groups of closely connected devices (e.g. a tank and the

input

output pumps) are controlled by dedicated PLCs that run on net-

worked computers physically located in proximity to the equipment. In

order to facilitate the transition from the simulated prototype to the real

system, the design of the simulator's architecture must take into account the

distributed nature of the manufacturing work cell.

Decision point

Simulator architecture: centralized or distributed?

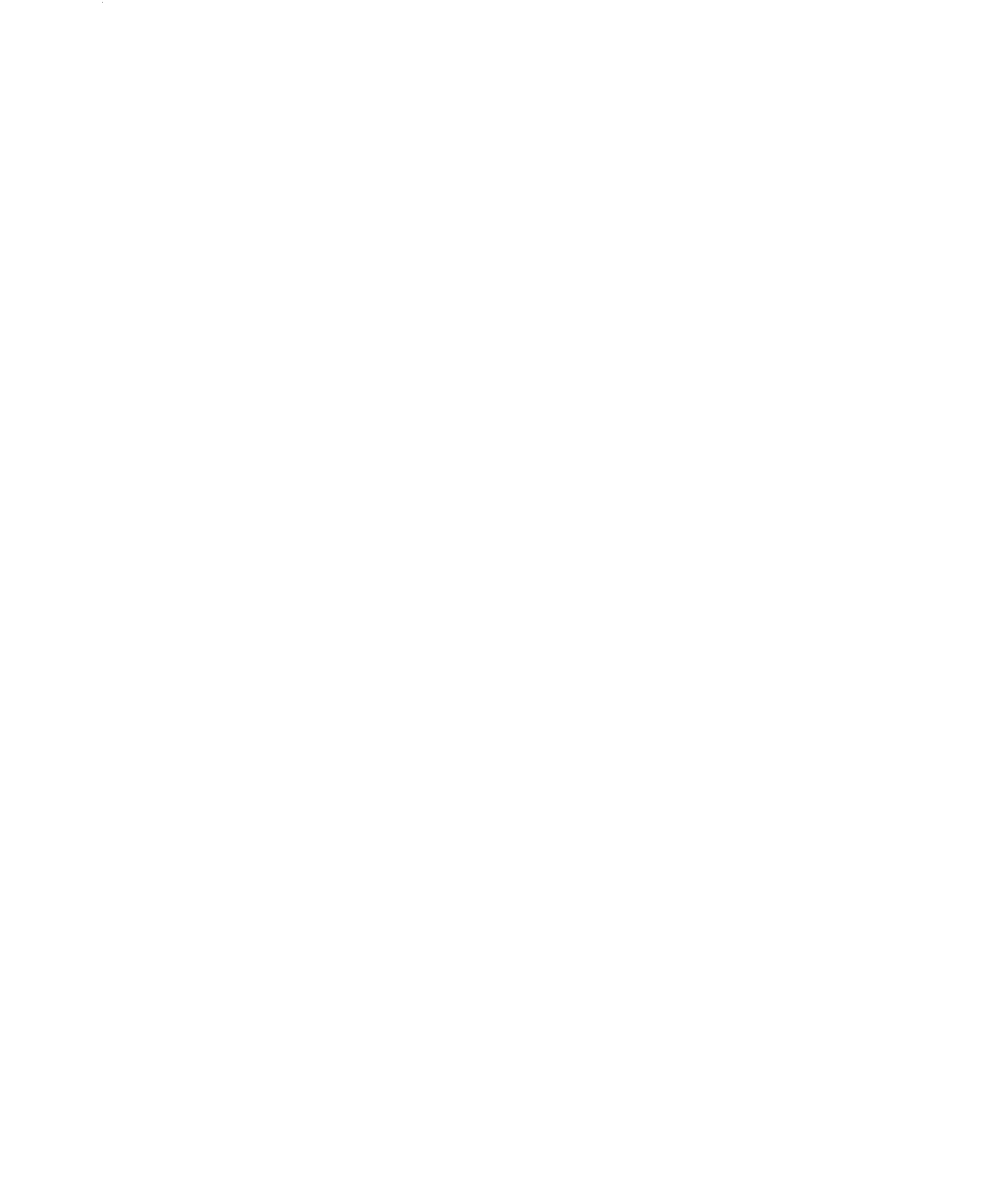

A first design solution consists in simulating the behaviour of each device

or group of devices as part of the behaviour of the PLC that controls their

functioning (Figure 13.5). This solution has a major drawback: the physical

constraints that characterize the paint flow between two tanks should be

enforced through the exchange of data between the corresponding PLCs.

This approach requires defining two different implementations of each PLC

for the control of the simulated work cell and of the real work cell, making

the results of the test cases performed in simulation useless.

A second design solution consists in simulating each physical device or

group of devices as independent applications that run on dedicated com-

puters connected to the PLCs through the network. The result is a fully

distributed simulator.

PLC

PLC

PLC

PLC

Figure 13.5

The symbiosis between simulated devices and PLCs