Java Reference

In-Depth Information

Table 9.5

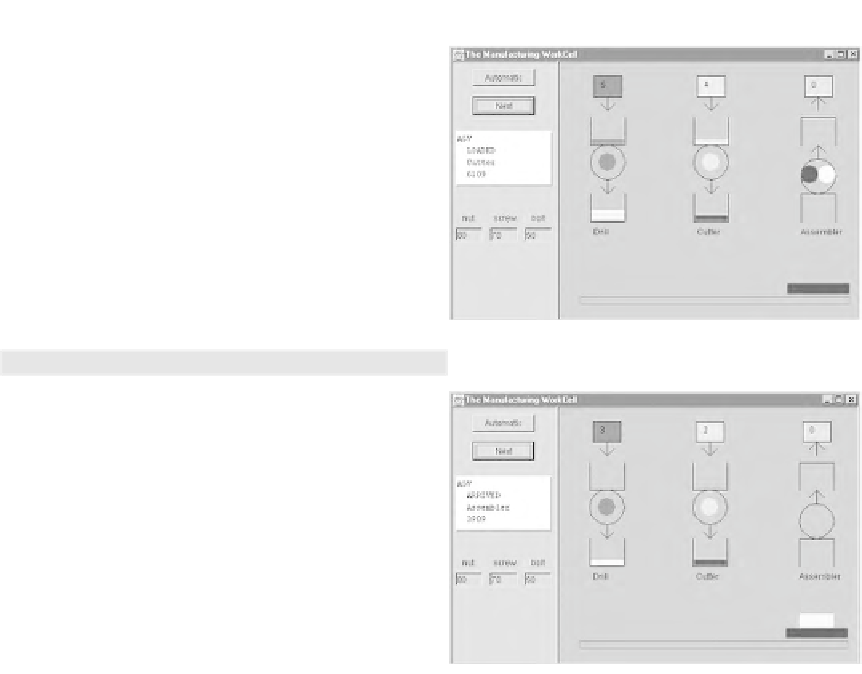

The sequence of events generated during the simulation and two GUI screen shots

Broadcaster

Event

Value

Time

NutSource

LOADED

Nut

809

ScrewSource

LOADED

Screw

1461

NutSource

LOADED

Nut

1694

Drill

WORKDONE

Drill

2309

ScrewSource

LOADED

Screw

2807

AGV

ARRIVED

Drill

2959

NutSource

LOADED

Nut

3181

AGV

UNLOADED

Drill

3259

Cutter

WORKDONE

Cutter

3261

Drill

WORKDONE

Drill

3809

AGV

ARRIVED

Assembler

3909

Broadcaster

Event

Value

Time

ScrewSource

LOADED

Screw

4101

NutSource

LOADED

Nut

4108

AGV

LOADED

Drill

4209

AGV

ARRIVED

Cutter

4859

ScrewSource

LOADED

Screw

4964

Cutter

WORKDONE

Cutter

5061

NutSource

LOADED

Nut

5124

AGV

UNLOADED

Cutter

5159

Drill

WORKDONE

Drill

5309

AGV

ARRIVED

Assembler

5809

AGV

LOADED

Cutter

6109

Copyright © 2005 Sun Microsystems, Inc. All rights reserved.

Reproduced by permission of Sun Microsystems, Inc.

9.6

■

Extension

A number of functional requirements have not been taken into consider-

ation in Prototype 2. The reader might want to develop a new prototype of

the work cell system that solves the design problems that have not been

addressed so far. Here is a list of possible extensions.

Class

Assembler

should implement the notification of the events

FULL

and

NOTFULL

to inform the AGV that the input buffer is full or is getting empty.

■

Class

Assembler

should manage two distinct input buffers for nuts and

screws; in fact if we model a single input buffer for both types of piece,

it might happen that the input buffer gets full of nuts (or screws). This

situation causes a deadlock, because the assembler extracts only pairs of

nuts and screws from the input buffer. Thus, if the buffer contains only

pieces of the same type, it will never start getting empty and there will

never be positions available for pieces of the other type.

■